High Speed Heavy-Duty Crusher for Tough Material Processing

Designed for hard and bulky materials, this high speed crusher features a robust motor for rapid crushing, wear-resistant components, and a large feed hopper—ideal for efficient processing of plastics, metals, rubber, and industrial waste in high-output manufacturing and recycling environments.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

Blue/WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysWeight:

540Brand:

PQProduct Description

Handling hard or bulky materials such as hard plastics, metal shavings, and thick rubber requires powerful and durable equipment to avoid inefficiency and frequent maintenance.

This machine has a high-torque motor for fast and powerful crushing, heat-treated alloy blades, and reinforced components to withstand abrasive materials. The extra-large feed inlet simplifies the loading process and reduces pre-treatment steps, and the balanced rotor design reduces vibration and ensures stable operation. Safety features such as overload protection and emergency shutdown ensure safe operation, and the adjustable screen supports customized particle size on demand. Whether it is a plastic recycling plant, a metal processing plant, or an industrial waste treatment scenario, it can provide efficient crushing performance to support high-load production processes.

Product Parameters

| Model | Power (kW) | Feeding Port Size (mm) |

Flat Blade Type (blade) |

Flap Blade Type (blade) |

Claw Blade Type (blade) |

Fixed Blade (handle) |

Crushing Capacity (kg/h) |

Body Size (cm) | Weight (kg) |

| MP180 | 2.2(3HP) | 180×160 | 6 | 2 | 50-100 | 75×55×91 | 120 | ||

| MP250 | 3.7(5HP) | 255×230 | 3 | 9 | 12 | 2 | 130-250 | 89×63×111 | 280 |

| MP300 | 5.5(7.5HP) | 310×260 | 3 | 9 | 15 | 2 | 220-300 | 110×70×121.5 | 350 |

| MP400 | 7.5(10HP) | 410×260 | 3 | 12 | 18 | 2 | 300-400 | 104×79.5×121 | 450 |

| MP500 | 11(15HP) | 510×275 | 6 | 15 | 21 | 2 | 460-550 | 124×95.5×154 | 500 |

| MP600 | 15(20HP) | 610×280 | 6 | 18 | 27 | 4 | 600-800 | 124×105×154 | 750 |

| MP700 | 22(30HP) | 710×340 | 6 | 21 | 27 | 4 | 700-900 | 140×122×188 | 1050 |

| MP800 | 30(40HP) | 810×440 | 6 | 24 | 30 | 4 | 700-900 | 150×133.5×200 | 1450 |

Key Features

✅Pure Copper Motor for Stability: The core components are made of pure copper motors, which have excellent conductivity, high temperature resistance, strong anti-wear ability, support long-term high-load operation, and ensure stable equipment operation under high-intensity operation.

✅Reinforced Soundproof Enclosure: The fuselage is designed with thickened steel and sound insulation materials to effectively absorb the vibration and noise generated by high-speed operation. The sealed knife chamber structure significantly reduces working noise and creates a quiet and comfortable operating environment.

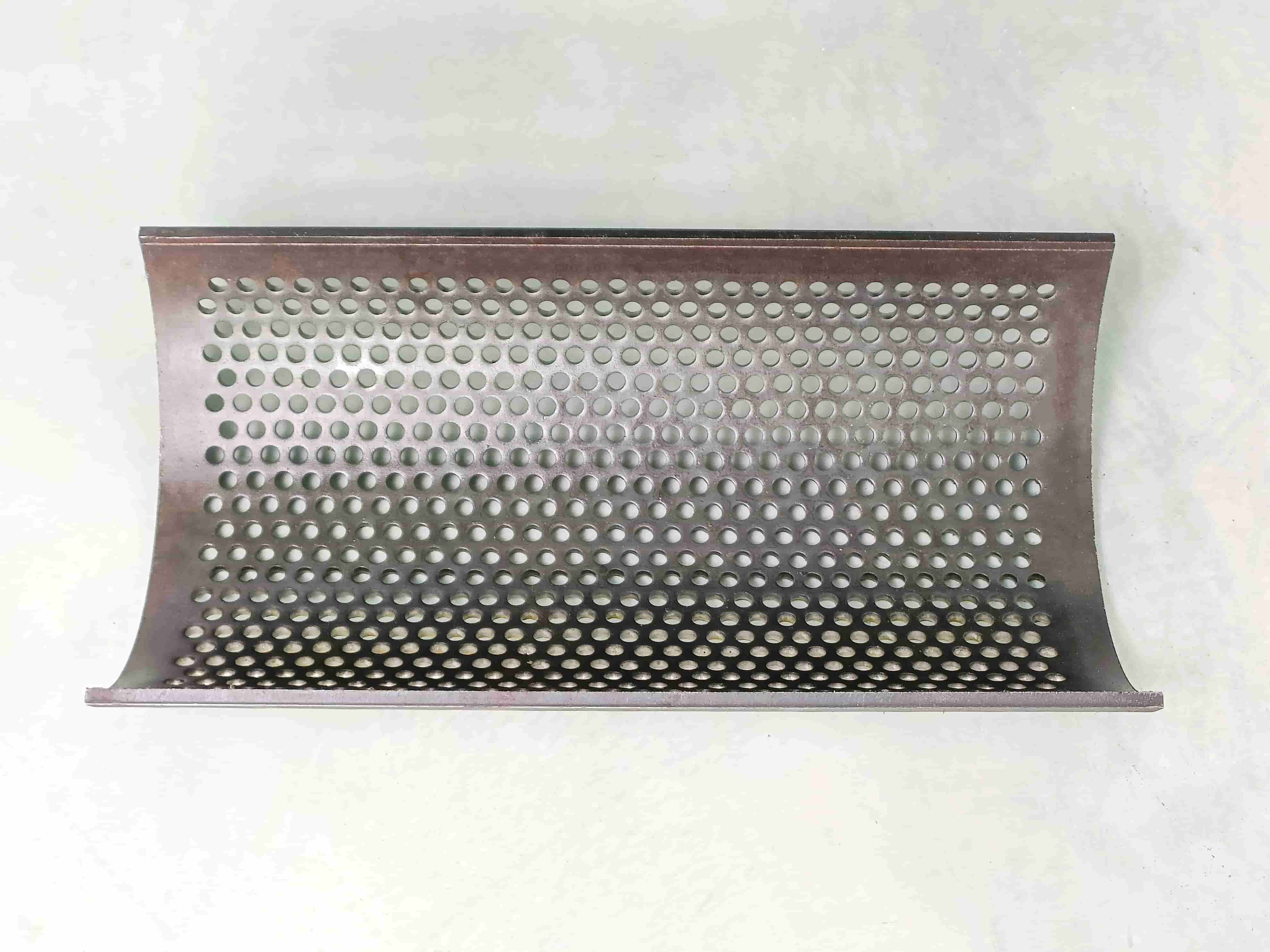

✅Customizable Screen for Particle Control: Equipped with replaceable screens, it supports a variety of aperture customization (from coarse crushing to fine grinding). According to the characteristics and production requirements of different materials, such as plastics, metals, rubber, etc., the size of crushed particles can be accurately controlled to meet diversified processing standards.

✅Portable Drawer for Easy Material Collection: A large-capacity material receiving drawer is set at the bottom, and a slide rail-type convenient disassembly structure is adopted. After the crushing is completed, the collected materials can be quickly extracted to reduce the loss of residual materials and improve the connection efficiency of subsequent processes.

✅Wide Feed Opening for Efficient Loading: The widened design of the feed port supports the direct delivery of large pieces of material without pre-cutting or crushing, saving the initial processing time. It is especially suitable for recycling plants and other scenes that require high-frequency feeding, and improves the overall crushing efficiency.

✅Anti-Splash Rubber Guard for Safety: The feeding port is equipped with an adjustable splash guard to effectively prevent material splashing during the crushing process, protect the safety of operators, and reduce material scattering in the workshop environment to maintain a neat production order.

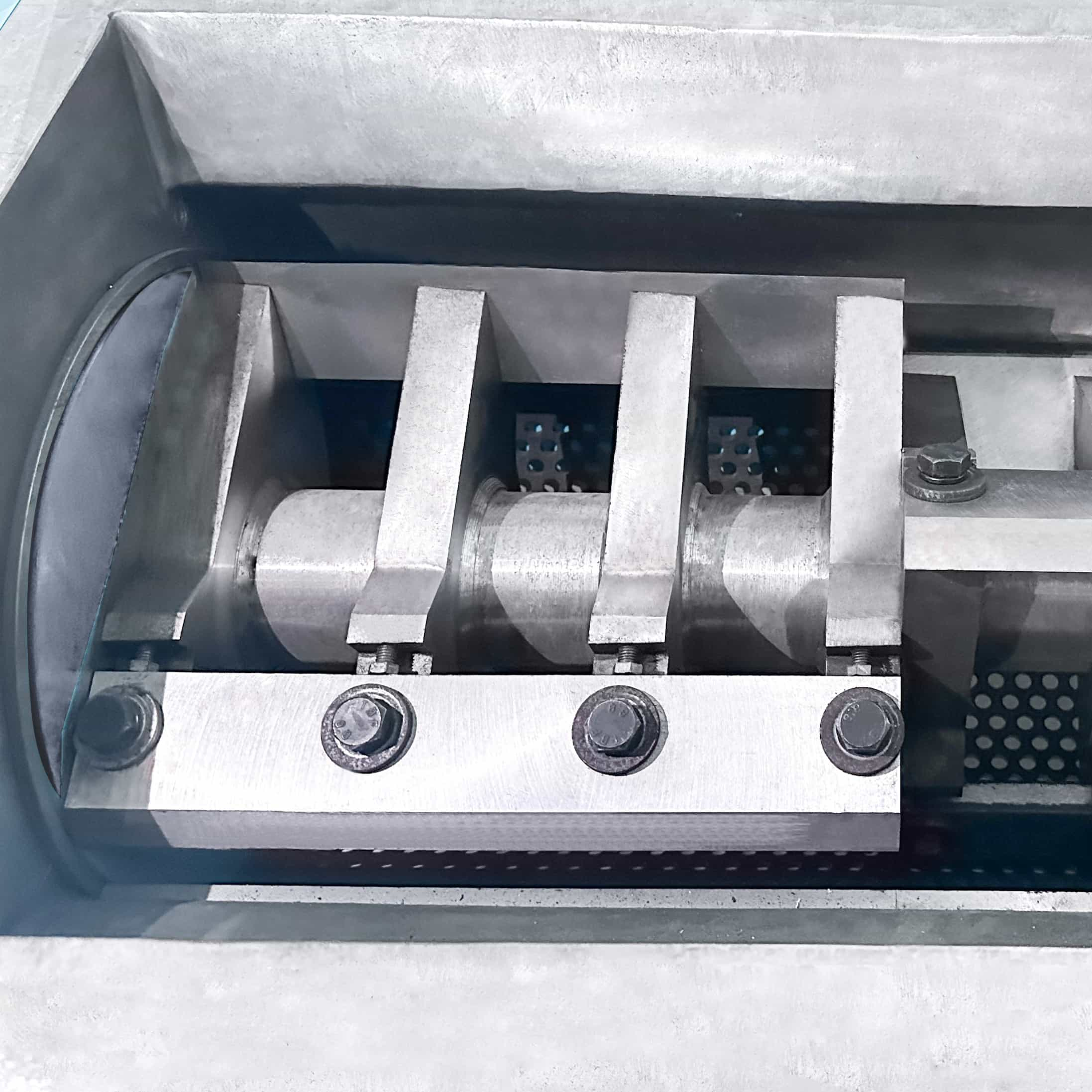

✅Reinforced Blade Chamber for Durability: The knife chamber is reinforced with thickened steel plates and heat-treated to improve hardness. It can withstand high-frequency impacts of hard plastics, reduce deformation and wear of the knife chamber, extend the service life of core components, and reduce maintenance costs.

Product Detail Display

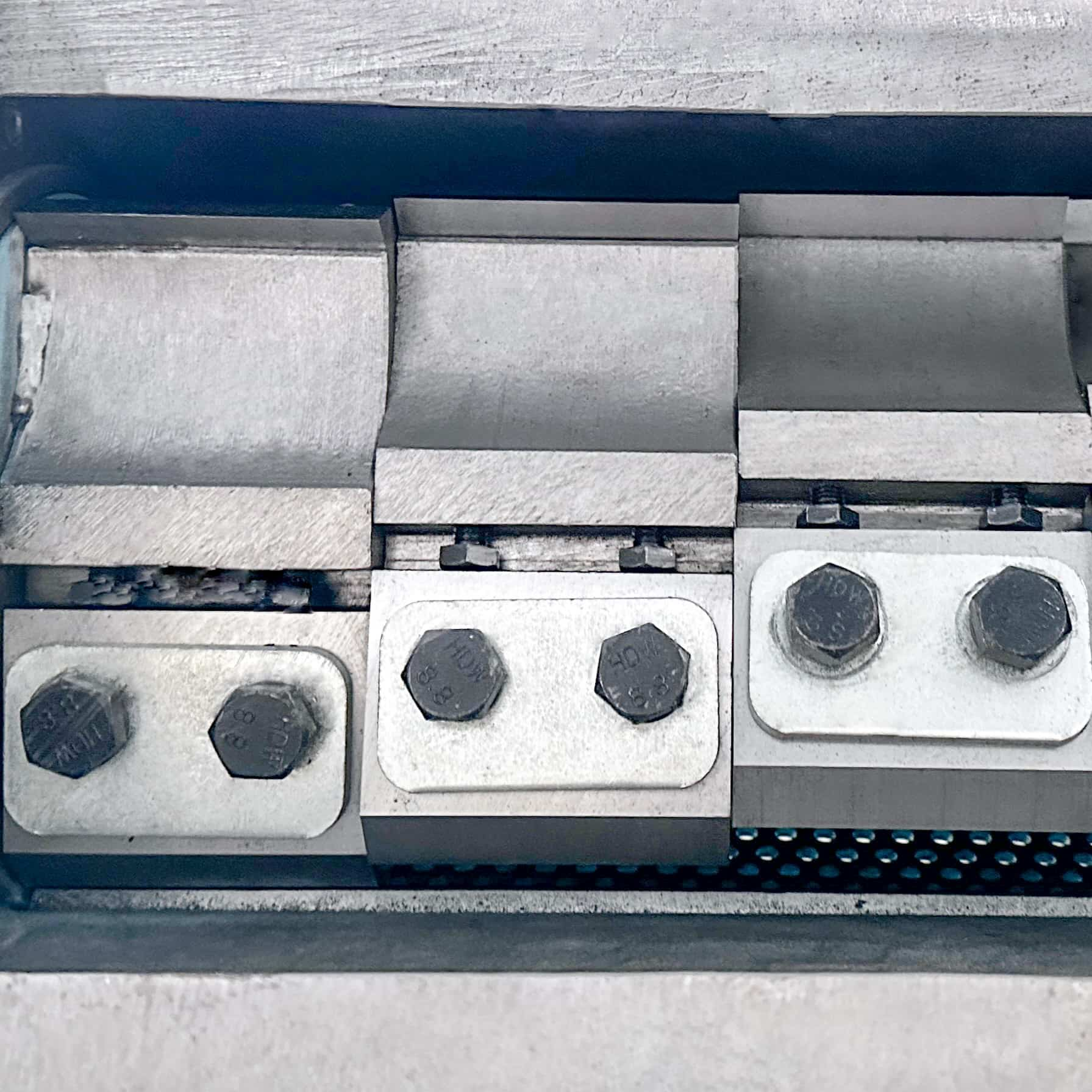

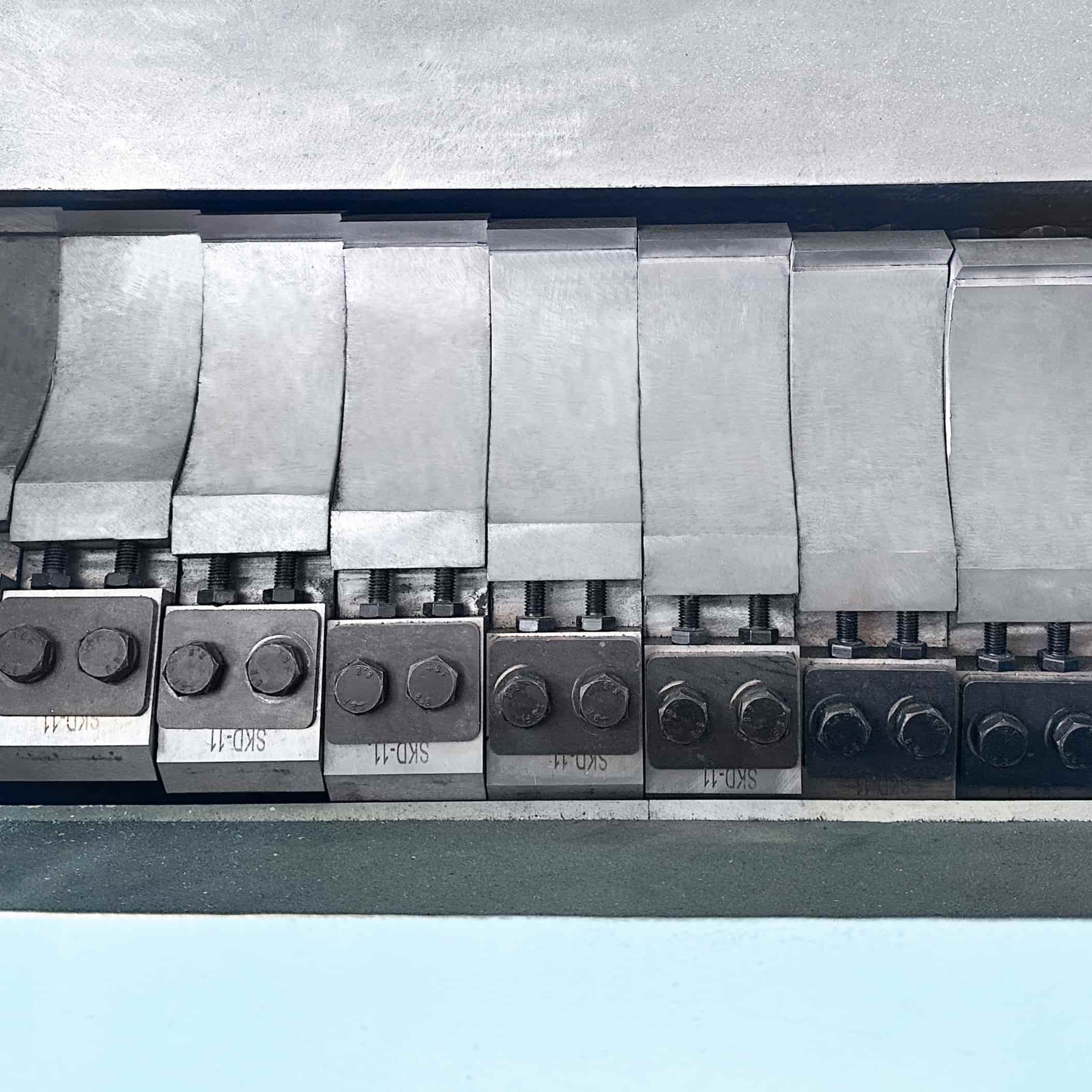

THREE KNIVES, EACH HAS ITS STRENGTHS

Made of high-quality alloy steel, sharp and wear-resistant, with high-efficiency crushing.

CRUSHING EFFECT DISPLAY

CUSTOMIZABLE MESH SIZE

The size of the material discharged depends on the size of the screen holes.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported