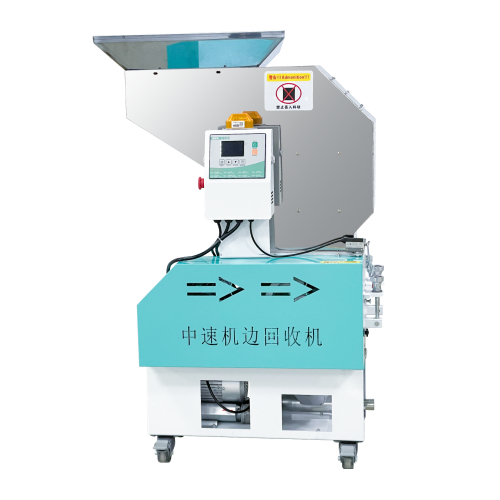

Specially designed for PC, PP, nylon, ABS, and other injection molding nozzle materials and scraps, the medium-speed crusher adopts stepped double-headed blades to achieve powerful, low-dust crushing and is equipped with a high-pressure feeding air pump and a quick-release maintenance structure. It is suitable for instant recycling at the machine side, effectively reducing labor costs and downtime losses.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

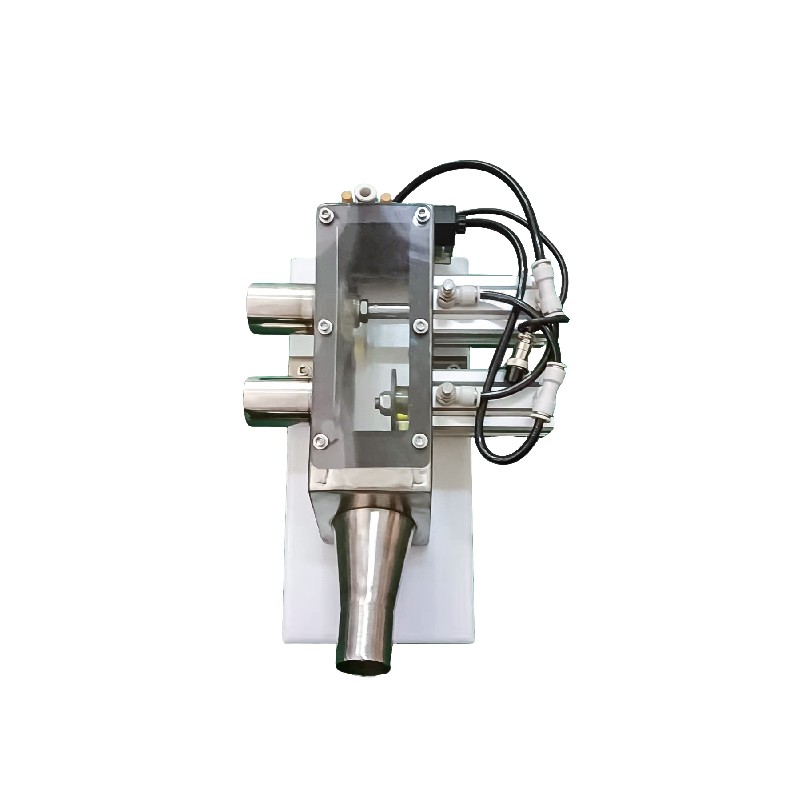

To process injection molding scraps such as PC shells, PP handles, and ABS connectors, equipment that takes into account both crushing force and dust control is required. The unique stepped double-headed blade (offset tooth design) of this machine generates high shear force and efficiently crushes tough plastic waste. The sealed chamber and splash-proof material skin simultaneously suppress dust spillage and achieve clean production. The built-in high-pressure feeding air pump automatically transports materials from the feed hopper to the crushing chamber, eliminating the manual feeding link and reducing the labor cost of busy production lines. The pure copper core motor ensures continuous, stable operation with low heat generation, and the quick-detachable knife holder supports the replacement of worn blades to solve the urgent problem of no spare blades after the blade is damaged. The safety design includes a visual observation window and a cover-opening shutdown limit switch to monitor the crushing process in real time. With an optional recycling system, an integrated solution for gate material crushing and recycling is constructed to improve the material reuse efficiency of plastic manufacturers.

Product Parameters

| Model | 240A | 300A | 360A | 420A |

| Voltage (V) | 3¢380V 50HZ | 3¢380V 50HZ | 3¢380V 50HZ | 3¢380V 50HZ |

| Crusher Power (kW) | 1.5 | 1.5 | 1.5 | 2.2 |

| Fan Power (W) | 370 | 550 | 550 | 550 |

| Feeding Port Size (mm) |

240*400 | 300*400 | 360*410 | 420*400 |

| Crushing Chamber (mm) |

235*270 | 300*260 | 360*260 | 415*260 |

| Fixed Blade | 2 pieces | 2 pieces | 2 pieces | 2 pieces |

| Moving Blade | 24 pieces (3 rows * 8 pieces) |

30 pieces (3 rows * 10 pieces) |

36 pieces (3 rows * 12 pieces) |

42 pieces (3 rows * 14 pieces) |

| Speed (r/min) | 960 | 960 | 960 | 960 |

| Recovery Capacity (kg/h) |

200 | 300 | 400 | 500 |

| Dimensions (mm) | 800*490*1375 | 800*560*1380 | 800*600*1395 | 800*680*1435 |

| Weight (kg) | 200 | 210 | 230 | 240 |

Key Features

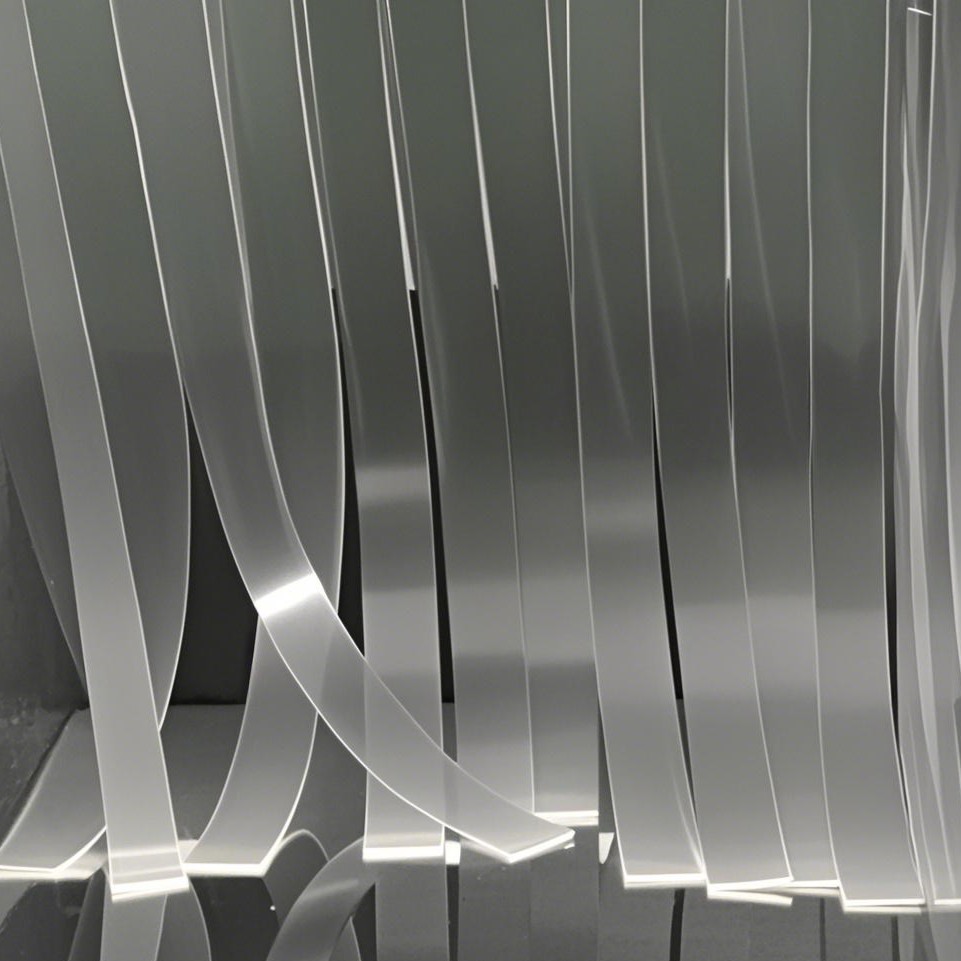

✅ Stepped Double-Headed Blade: The stepped double-headed blade design is adopted, and the dislocated tooth structure forms a high shear force, which can easily crush tough nozzle materials such as PC, PP, nylon, ABS, etc. The crushed particles are uniform, and the dust content is low, avoiding the powder pollution and raw material waste of traditional crushing.

✅ High-Pressure Feeding Air Pump: The built-in high-pressure feeding air pump system automatically sucks the scraps from the machine into the crushing chamber, without manual handling and feeding, saving feeding time.

✅ Quick-Detachable Knife Holder: The blade and the knife holder adopt a quick-detachable structure. When the knife is damaged, it can be quickly replaced without tools, solving the shutdown problem caused by sudden knife damage.

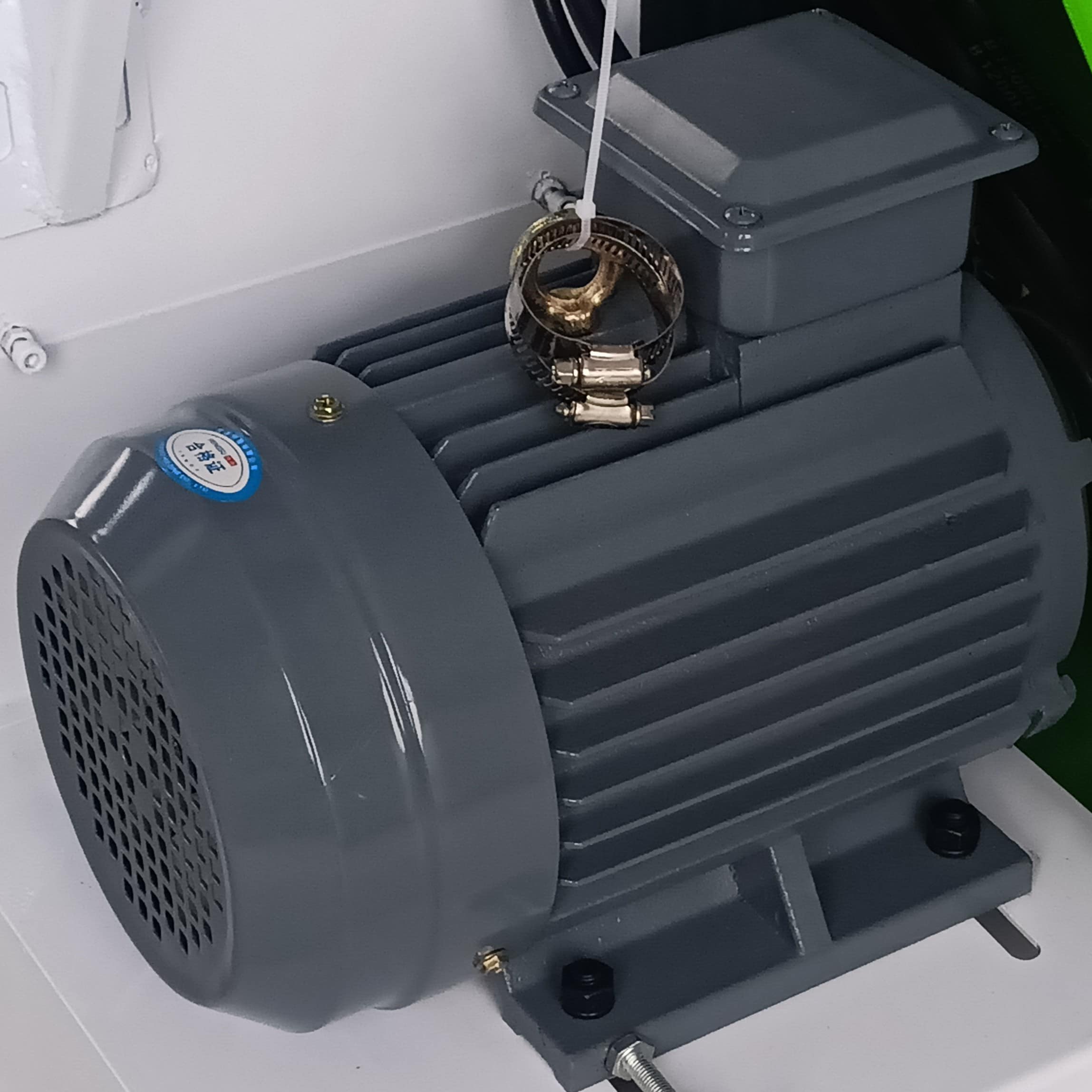

✅Pure Copper Core Motor: Equipped with a pure copper core motor, it has excellent conductive and heat dissipation performance and does not get hot during continuous operation. With a fully sealed crushing chamber and a splash-proof material cover, it effectively isolates dust intrusion, reduces motor loss, and extends the service life of the equipment.

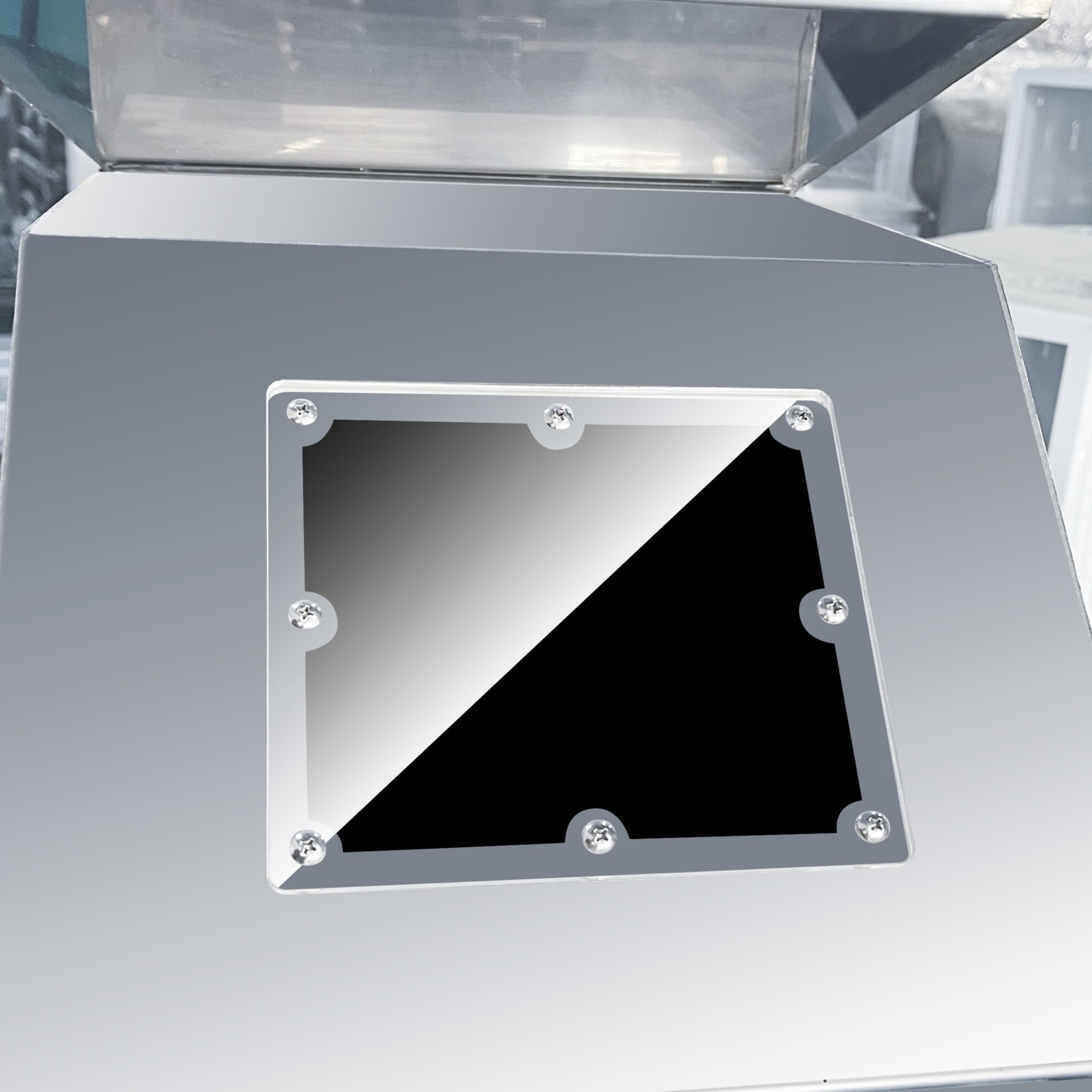

✅Safety Visualization: The explosion-proof visualization window monitors the crushing status in real time, and the limit switch realizes automatic power off when the cover is opened to ensure safe operation.

✅Vacuum Air Pump Filter: Equipped with a vacuum air pump filter, it can efficiently filter the fine dust generated during the feeding process, ensure the cleanliness of the workshop air, and reduce the damage of dust to the precision parts of the injection molding machine.

Product Detail Display

Combined with A Recycling System to Improve Efficiency

There are three matching schemes.

BLADE UPGRADE

Double-Ended Claw-Shaped Cutter

The stepped double-ended blade has a strong crushing effect,

low dust and low maintenance cost.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported