Designed for hassle-free operation, this industrial AC features a built-in stainless steel pipe system to prevent scaling, requires zero regular cleaning, and uses a large-capacity water tank for months of use without connecting to a water supply—ideal for remote or water-scarce industrial sites.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQ

Product Description

When choosing an industrial air conditioner, consider cooling capacity, energy consumption, and maintenance convenience. This machine provides dual power configurations of 5HP and 15HP: the 5HP model covers 150-200㎡, and consumes only 4-5 degrees of electricity per day. The 15HP model covers 650-700㎡, and consumes 11 degrees of electricity per day, both of which can achieve powerful cooling that is 8-10℃ lower than the room temperature.

The core advantage comes from the fully sealed stainless steel piping system, which is resistant to scaling and corrosion, and eliminates the cost of regular cleaning. The large-capacity water tank supports long-term operation for several months without the need for external water pipes, which is particularly suitable for warehouses, workshops, or remote sites with inconvenient water sources.

Different from traditional air conditioners that require frequent maintenance and high water consumption, this machine perfectly combines powerful cooling, energy saving, and power saving with convenient use, ensuring a comfortable and efficient industrial environment without downtime losses and additional maintenance expenses.

Different Designs of Products

Product Parameters

| Vertical Louvers | ||||

| Model Number | 5HP | 7HP Single Fan | 7HP Dual Fan | 10HP Dual Fan |

| Compressor Power (kW) | 3.75 | 7 | 7 | 10 |

| Cooling Capacity (kW) | 18 | 25 | 25 | 36 |

| Cold Air Outlet (mm) | 56*54 | 56*54 | 44*111 | 44*111 |

| Motor Power (kW) | 0.09 | 0.25 | 0.18 | 0.18 |

| Head (M) | 10~15 | 10~15 | 10~15 | 10~15 |

| Rated Power (kW) | 4.6 | 6 | 5.93 | 8.18 |

| Temperature Control Range (°C) | 13-30 | 13-30 | 13-30 | 13-30 |

| Refrigeration Area (㎡) | 150-200 | 250-300 | 300 | 400-450 |

| Refrigerant Type | R410A | R410A | R410A | R410A |

| Length, Width, and Height (cm) | 80*60*168 | 80*60*168 | 84*73*201 | 84*73*201 |

| Weight (kg) | 170 | 180 | 230 | 240 |

| Motor Power (kW) | 0.5 | 0.5 | 1 | 1 |

| Air Volume (m³/h) | 10300 | 10300 | 10300*2 | 10300*2 |

| Heat Dissipation Ambient Temperature (°C) | 40 | 40 | 40 | 40 |

| External Machine Size (cm) | 74*22*107 | 84*22*117 | 84*22*117 | (74*22*107)*2 |

| Weight (kg) | 35 | 40 | 40 | 35*2 |

| Vertical Jet Model | |||||

| Model Number | 5HP | 7HP | 10HP | 12HP | 15HP |

| Compressor Power (kW) | 3.75 | 5.25 | 7.5 | 9 | 10.5 |

| Cooling Capacity (kW) | 18 | 25 | 36 | 43 | 54 |

| Rated Power (kW) | 5.1 | 7.1 | 10.64 | 12.14 | 14.6 |

| Temperature Control Range (°C) | 13-30 | 13-30 | 13-30 | 13-30 | 13-30 |

| Motor Power (kW) | 0.52 | 1 | 0.52*2 | 0.52*2 | 1*2 |

| Air Volume (m³/h) | 3350 | 4200 | 6700 | 6700 | 8400 |

| Refrigeration Area (㎡) | 150-200 | 250-300 | 400-450 | 500-550 | 650-700 |

| Refrigerant Type | R410A | R410A | R410A | R410A | R410A |

| Length, Width, and Height (cm) | 80*60*197 | 80*60*197 | 131*64*212 | 131*64*212 | 131*64*212 |

| Weight (kg) | 166 | 180 | 330 | 340 | 365 |

| Motor Power (kW) | 0.5 | 0.5 | 0.5*2 | 0.5*2 | 0.5*2 |

| Air Volume (m³/h) | 10300 | 10300 | 10300*2 | 10300*2 | 10300*2 |

| Heat Dissipation Ambient Temperature (°C) | 40 | 40 | 40 | 40 | 40 |

| External Machine Size (cm) | 74*22*107 | 84*22*117 | (74*22*107)*2 | (74*22*107)*2 | (84*22*117)*2 |

| Weight (kg) | 35 | 40 | 35*2 | 35*2 | 40*2 |

| Ceiling Jet Model | ||

| Model Number | 5HP | 7HP |

| Compressor Power (kW) | 3.75 | 5.25 |

| Cooling Capacity (kW) | 18 | 25 |

| Rated Power (kW) | 5.1 | 7.1 |

| Temperature Control Range (°C) | 13-30 | 13-30 |

| Motor Power (kW) | 0.52 | 1 |

| Air Volume (m³/h) | 3350 | 4200 |

| Cooling Area (㎡) | 150-200 | 250-300 |

| Refrigerant Type | R410A | R410A |

| Length, Width, and Height (cm) | 118*86*76 | 116*86*76 |

| Weight (kg) | 166 | 180 |

| Motor Power (kW) | 0.5 | 0.5 |

| Air Volume (m³/h) | 10300 | 10300 |

| Heat Dissipation Ambient Temperature (°C) | 40 | 40 |

| Ternal Machine Size (cm) | 74*22*107 | 84*22*117 |

| Weight (kg) | 35 | 40 |

Key Features

✅ Flexible Selection of Multiple Powers: Provide a variety of power models (covering 150-700㎡+ space), accurately matching the cooling needs of workshops and factories of different sizes.

✅ 8-10℃ Strong Cooling: Break through the cooling limitations of traditional industrial air conditioners, and the actual temperature is 8-10℃ lower than the room temperature, effectively meeting the heat dissipation needs of high-temperature environments such as injection molding workshops and metal processing.

✅ Long-Lasting Water Tank Design: The built-in large-capacity water tank can be used for several months after adding water once, without the need for external water pipes, completely getting rid of water source restrictions, especially suitable for water shortage scenarios such as remote warehouses and off-grid factories.

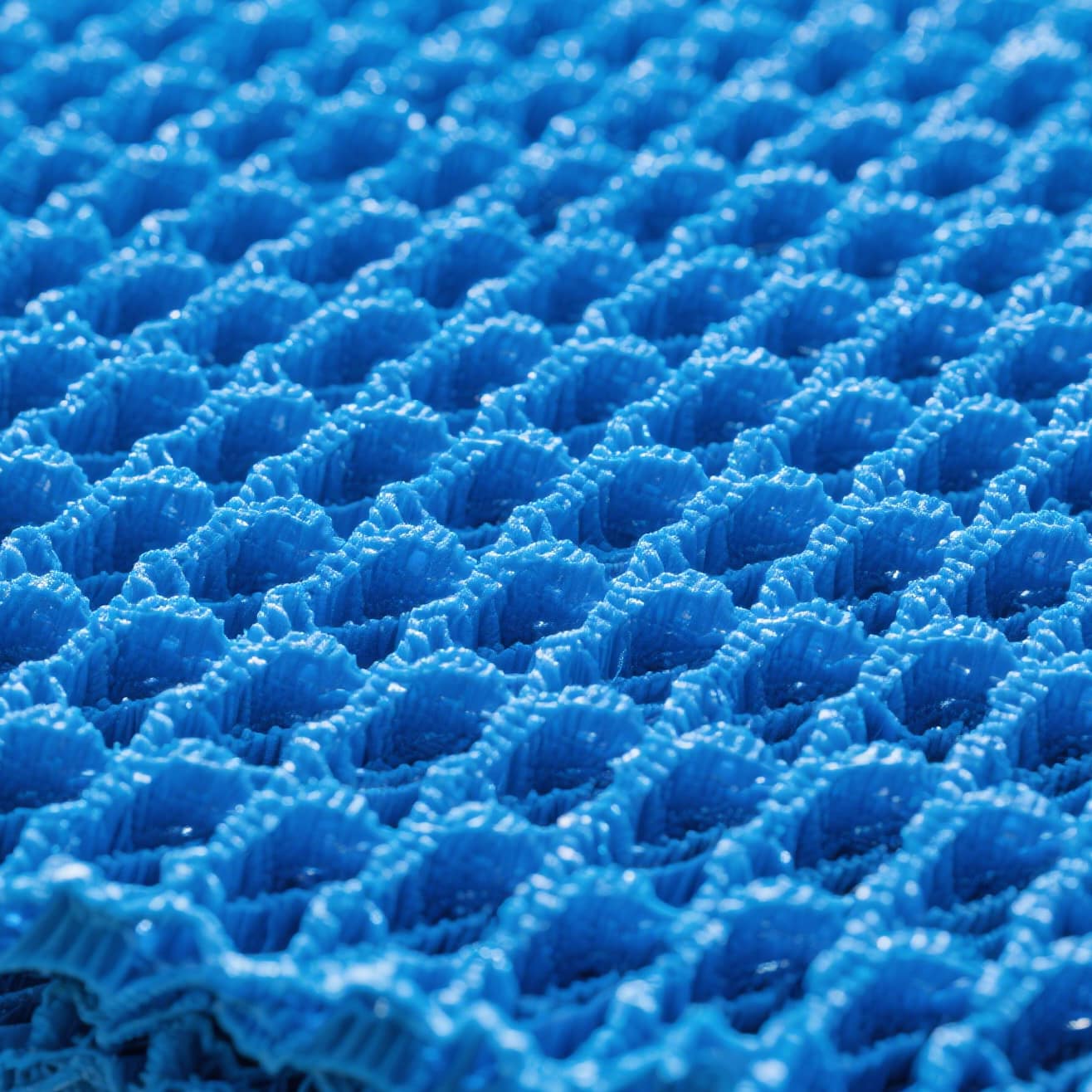

✅Maintenance-Free Stainless Steel Pipeline: The fully enclosed stainless steel pipeline system is corrosion-resistant and anti-scaling, and does not require chemical cleaning or disassembly, eliminating pipeline blockage and maintenance costs from the source, and extending the equipment life by 30%.

✅No Water Consumption and Zero Evaporation: Adopting a sealed water circulation design, there is no evaporation loss, and it reduces water consumption by 90% compared with traditional wet cooling air conditioners, meeting green manufacturing and environmental protection requirements.

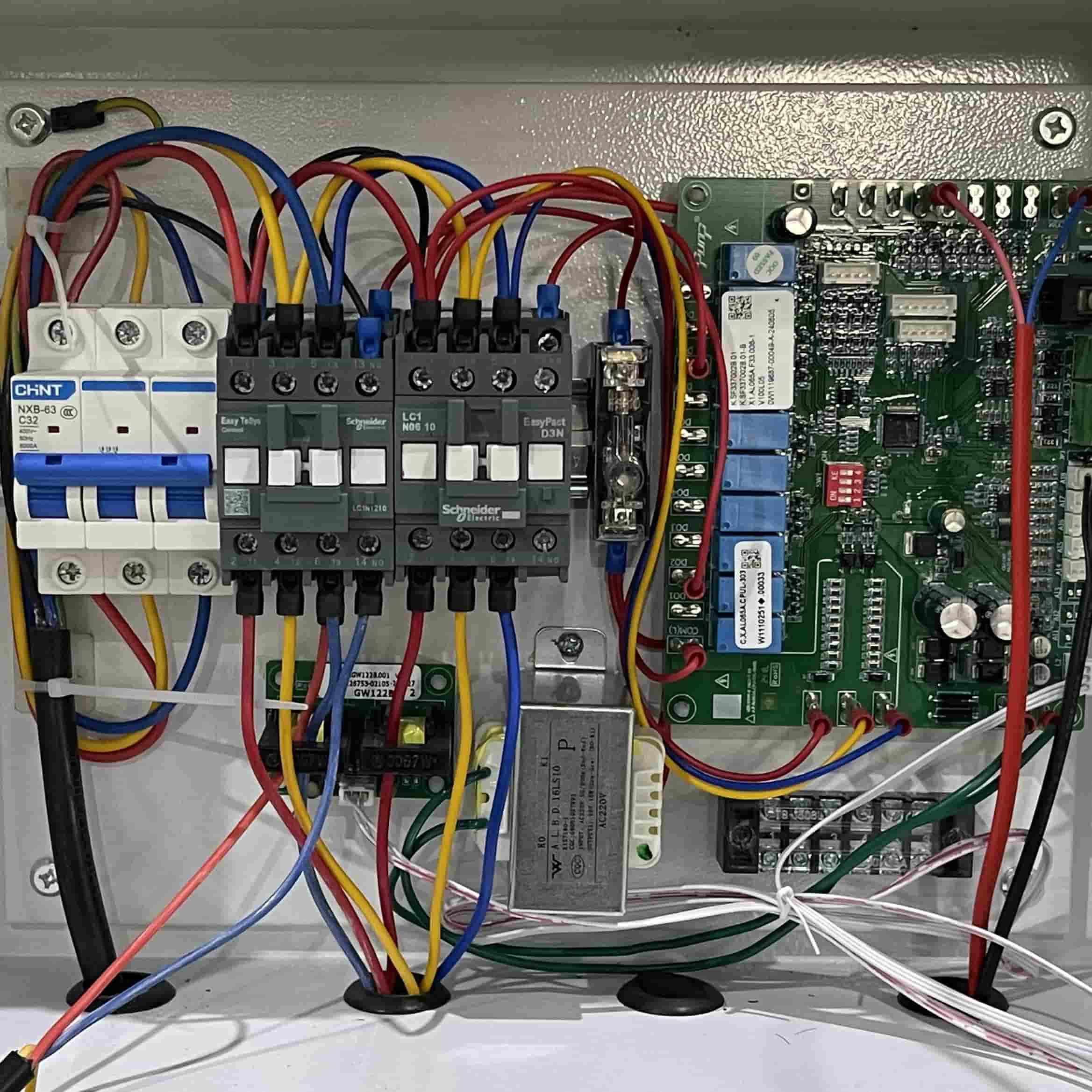

✅Intelligent Fault Warning: Built-in sensors monitor the operating status in real time, automatically shut down, and alarm when an abnormality occurs, reducing equipment loss and production interruption risks.

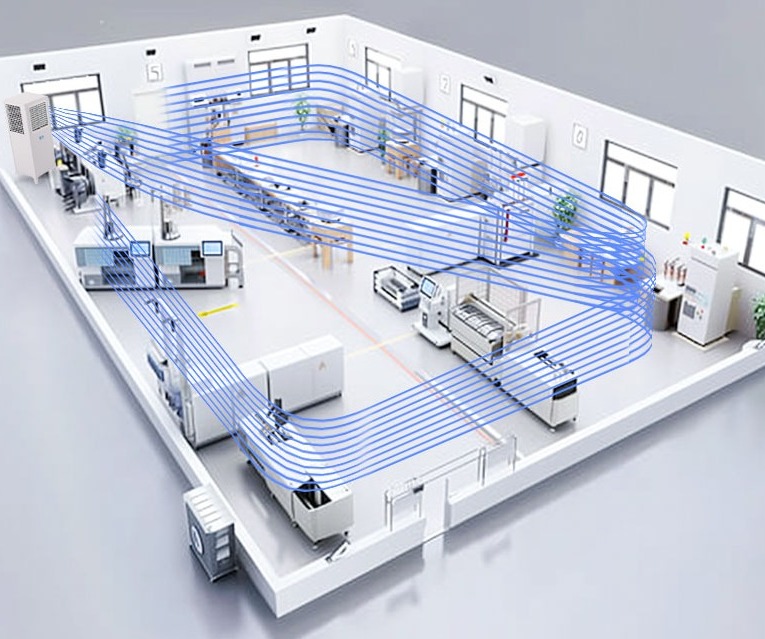

✅Multi-scenario Adaptation: Widely used in injection molding workshops, metal processing plants, logistics warehouses, new energy battery plants, etc., supporting 24-hour continuous high-load operation.

Product Detail Display

printing factories, and electronics factories.

ADJUSTABLE THREE-WAY AIR OUTLET

LARGE AREA COOL EXPERIENCE

120° adjustable outlet air design,

Achieve a large area cold air supply.

360° ADJUSTABLE SPHERICAL AIR OUTLET DESIGN

LARGE AREA WIDE ANGLE AIR SUPPLY

INCREASE THE COOLING SPEED OF A LARGE SPACE

Large power fan, long-distance air supply.

Provides even cooling for large spaces.

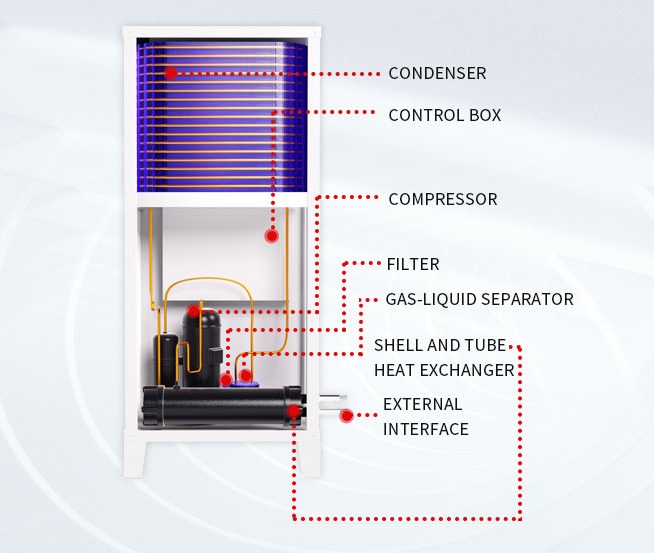

STRUCTURE ANALYSIS OF

EVAPORATIVE COOLING AIR CONDITIONING

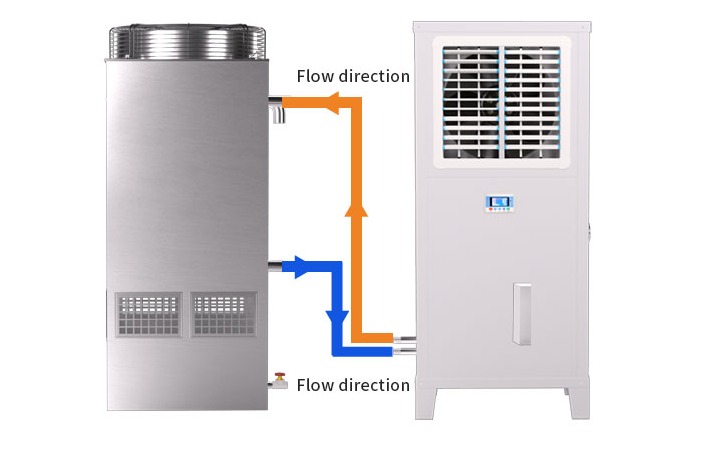

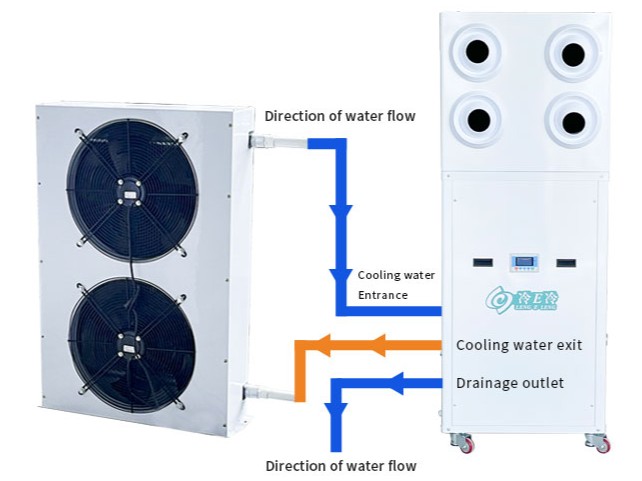

SCHEMATIC DIAGRAM OF AIR-COOLED CONNECTION

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported