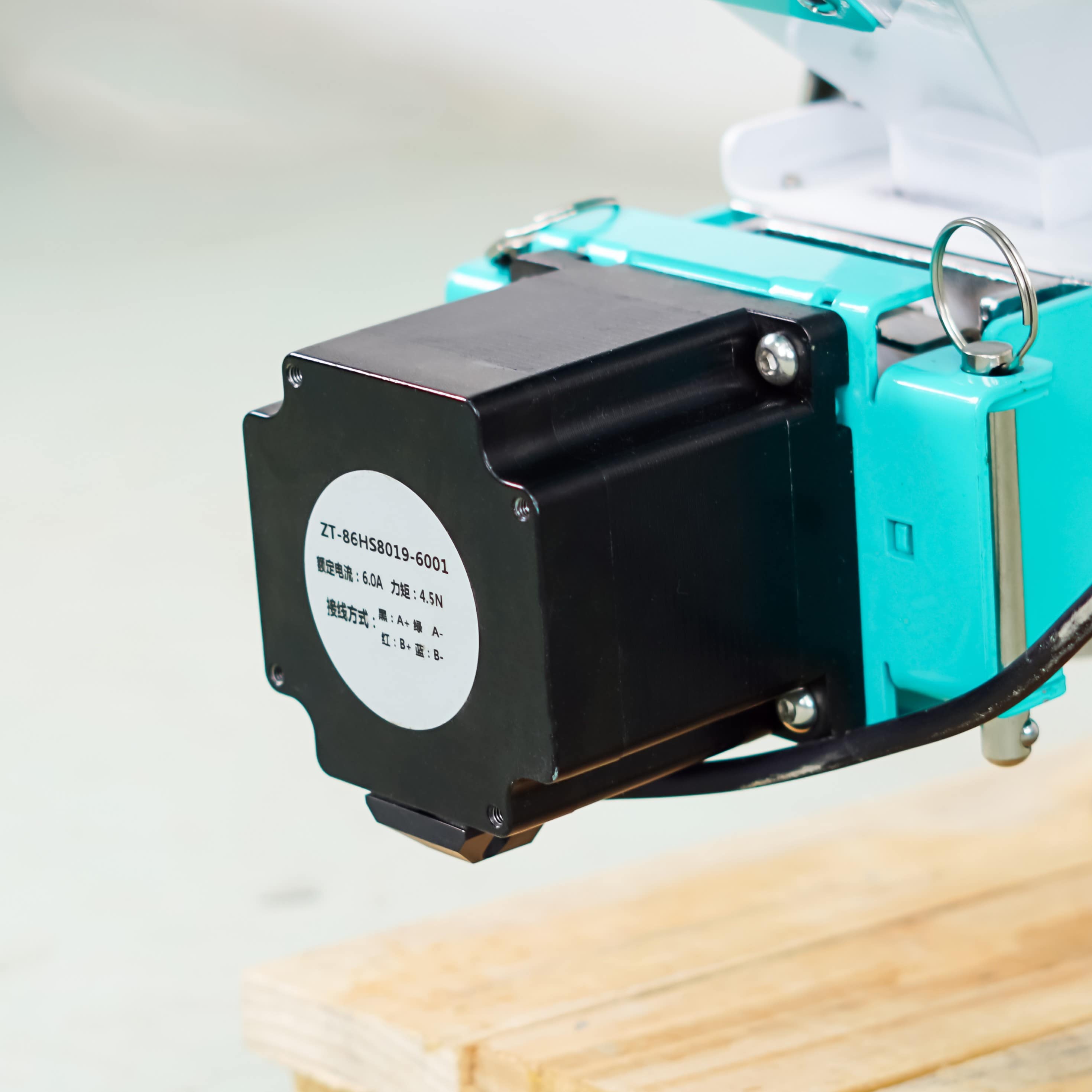

The intelligent metering masterbatch machine adopts revolutionary DC brushless drive technology, eliminating the need for lubrication and maintenance of traditional gear motors. Its microcomputer control system ensures excellent metering accuracy. The modular quick-release structure allows the equipment to easily switch between masterbatch and additive production lines. The standard three-tube magnet protection system effectively absorbs metal objects.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

Our Metering Masterbatch Machine is designed for continuous and efficient production: the chrome-plated screw resists corrosion and wear, the modular assembly enables quick cleaning and maintenance, and the intelligent memory system stores multiple sets of formula parameters. Dual configuration options are flexible, and the standard three-tube magnet protection system protects the molding machine. The optional agitator enhances the mixing uniformity, meeting the full-scenario needs from single-color to multi-color masterbatch production. This advanced equipment ensures consistent color dispersion and precise additive proportioning, making it an essential solution for injection molding, extrusion applications.

Product Parameters

| Type | Single Color Master | Two-Color Machine | ||||

| CMS-20-1 | CMS-16-1 | CMS-12-1 | CMS-20-2 | CMS-16-2 | CMS-12-2 | |

| Power Supply | 1Ф 220V 50Hz | |||||

| Stepper Motor Model | 86 | 86 | 86 | 86*2 | 86*2 | 86*2 |

| Power of Agitator (W) | 40※ | 40※ | 40※ | 40※ | 40※ | 40※ |

| Screw Type | 24 | 16 | 12 | 24×2 | 16×2 | 12×2 |

| Generated Quantity (kg/h) | 1.4-14 | 0.72-7.2 | 0.3-3 | 1.4-14×2 | 0.72-7.2×2 | 0.3-3×2 |

| Storage Hopper (L) | 9 | 9 | 9 | 9×2 | 9×2 | 9×2 |

| Reduction Ratio | 1:35 | 1:35 | 1:35 | 1:35 | 1:35 | 1:35 |

| Overall Dimensions (with agitation) | ||||||

| H (mm) | 570 | 570 | 570 | 570 | 570 | 570 |

| W (mm) | 570 | 570 | 570 | 990 | 990 | 990 |

| D (mm) | 280 | 280 | 280 | 280 | 280 | 280 |

|

Net Weight (including electric box) (kg) |

27 | 27 | 27 | 38 | 38 | 38 |

Key Features

✅ Maintenance-Free Operation–Brushless DC motor eliminates lubrication needs and reduces downtime.

✅ Smart Memory Function–Automatically stores and recalls production parameters.

✅ Precision Microcomputer Control–Intelligent calculation ensures consistent dosing accuracy.

✅ Enhanced Durability–Chrome-plated screws resist wear for extended service life.

✅ Flexible Configuration–Modular design allows easy assembly/disassembly and component interchange.

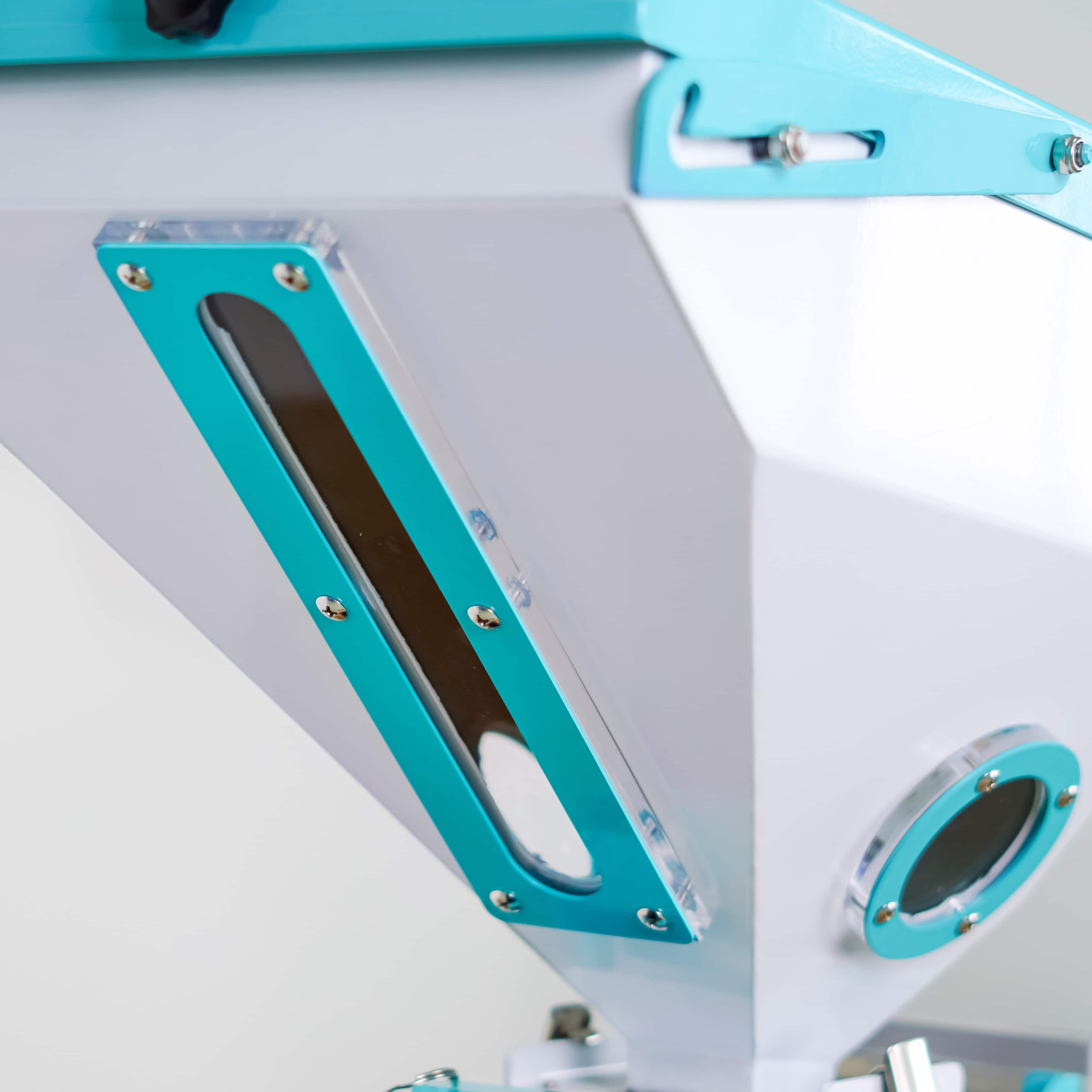

✅ Material Protection–Standard magnetic base (3-tube) prevents metal contamination (single-color models).

✅ Optional Mixing System–Dual-shaft mixer available for uniform blending (standard on dual-color models).

✅ Safety Compliance–Available with CE-certified European safety circuits.

Product Detail Display

FOUR TYPES OF HOPPERS ARE AVAILABLE

Stainless Steel Thickening

PLC SEVEN-INCH TOUCH COLOR SCREEN

The machine can be started quickly.

The high-pressure vacuum air pump has strong wind power and fast feeding.

Equipped with a recycling system. No manual loading is required.

HIGH-PRECISION CONTROLLER

More Accurate Color Mixing

The controller's unique compensation optimization concept ensures

that the metering of additives is always accurate.

FAQ

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported