Low-Dust Low-Noise Slow Speed Crusher for Gentle Material Processing

Designed specifically for industrial material handling, the slow pulverizer uses axial sprocket drive to achieve stable, low-wear operation. It is equipped with a low-noise, dust-free design and an adjustable pneumatic pusher to easily handle thick and bulk materials. It is the preferred solution for reliable and efficient pulverization in industries such as plastics, rubber, and recycling.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQ

Product Description

When traditional crushers process thick or irregular materials, they often face problems such as loud noise, high dust content, and unstable feeding, which leads to frequent maintenance and production interruptions. This machine uses a durable axial sprocket drive system to reduce mechanical stress on the bearings, and runs more smoothly and has a longer life than traditional designs. The adjustable pneumatic pusher gently pushes tough or large materials into the crushing chamber, reducing impact and blockage.

The sturdy mechanical structure and humanized design make it suitable for heavy-duty scenarios such as plastic recycling and rubber scrap processing, taking into account safety, hygiene, and stable performance.

Product Parameters

| Model | YS-MS1HP | YS-MS2HP | YS-MS3HP | YS-MS5HP |

| Feeding Port Size (mm) |

320×255 | 320×430 | 320×430 | 410×470 |

| Motor Power (kW) |

1.1 | 1.5 | 2.2 | 4 |

| Pineapple Blade | 3 | 3 | 4 | 4 |

| S Blade | 2 | 2 | 3 | 3 |

| Fixed Blade | 6 | 6 | 8 | 8 |

| Blade Material | SKD-11 | SKD-11 | SKD-11 | SKD-11 |

| Blade Structure | Claw Knife + Pineapple Knife |

Claw Knife + Pineapple Knife |

Claw Knife + Pineapple Knife |

Claw Knife + Pineapple Knife |

| Particle Size | 5-6mm | 6-8mm | 6-8mm | 6-8mm |

| Spindle Speed | 40r/min | 40r/min | 40r/min | 40r/min |

| Operation Sound | 60-70dB | 60-70dB | 60-70dB | 60-70dB |

| Weight (kg) | 150 | 200 | 260 | 750 |

| Body Size (cm) (Length, Width, and Height) |

90×50×130 | 105×55×135 | 115×55×135 | 125×56×166 |

| Grinding Chamber Size |

245*250 | 305*305 | 310*415 | 370*430 |

Key Features

✅Double-Layer Sound Insulation and Silent Design: The body adopts double-layer sound insulation material, which significantly reduces the operating noise and meets the noise reduction and environmental protection needs of various workshops.

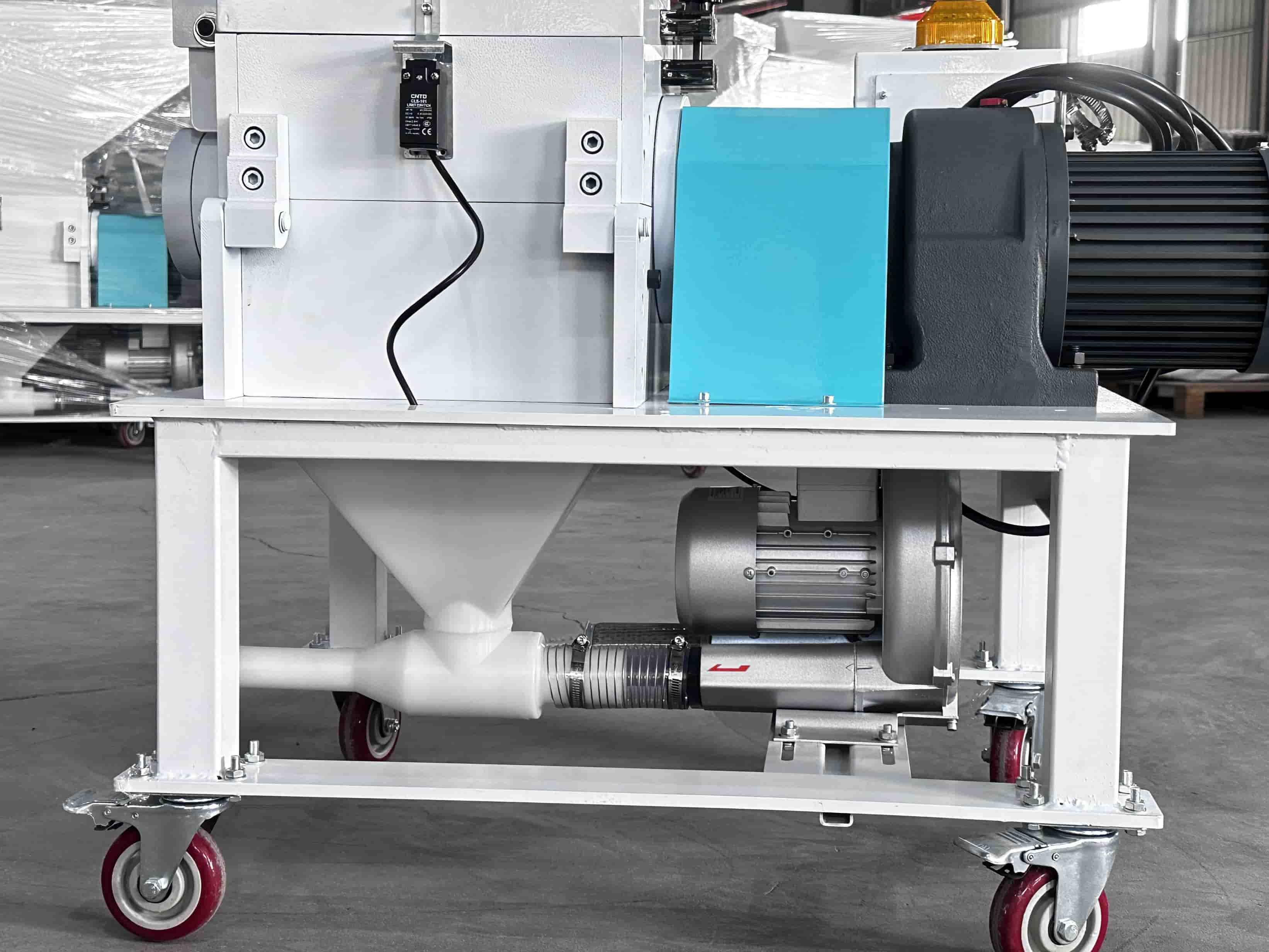

✅Automatic Recycling System: Built-in intelligent recycling system, automatically separates and collects particles after crushing, without manual work, improves crushing and recycling efficiency, and adapts to automated production processes.

✅Intelligent Timing and Flexible Control: Supports custom power-on and off time settings, can automatically start and stop according to production plans, avoids manual operation errors, saves energy, and is suitable for multi-shift or unattended scenarios.

✅Pure Copper Motor: The core components are made of pure copper motors, which have excellent conductivity, high temperature resistance, and wear resistance, ensuring stable operation of the equipment under high load, and reducing maintenance costs.

✅Universal Wheel Design: Equipped with universal wheels with brake function, supports 360° flexible movement and stable positioning, easily adapts to different workstation adjustments, and improves equipment deployment flexibility.

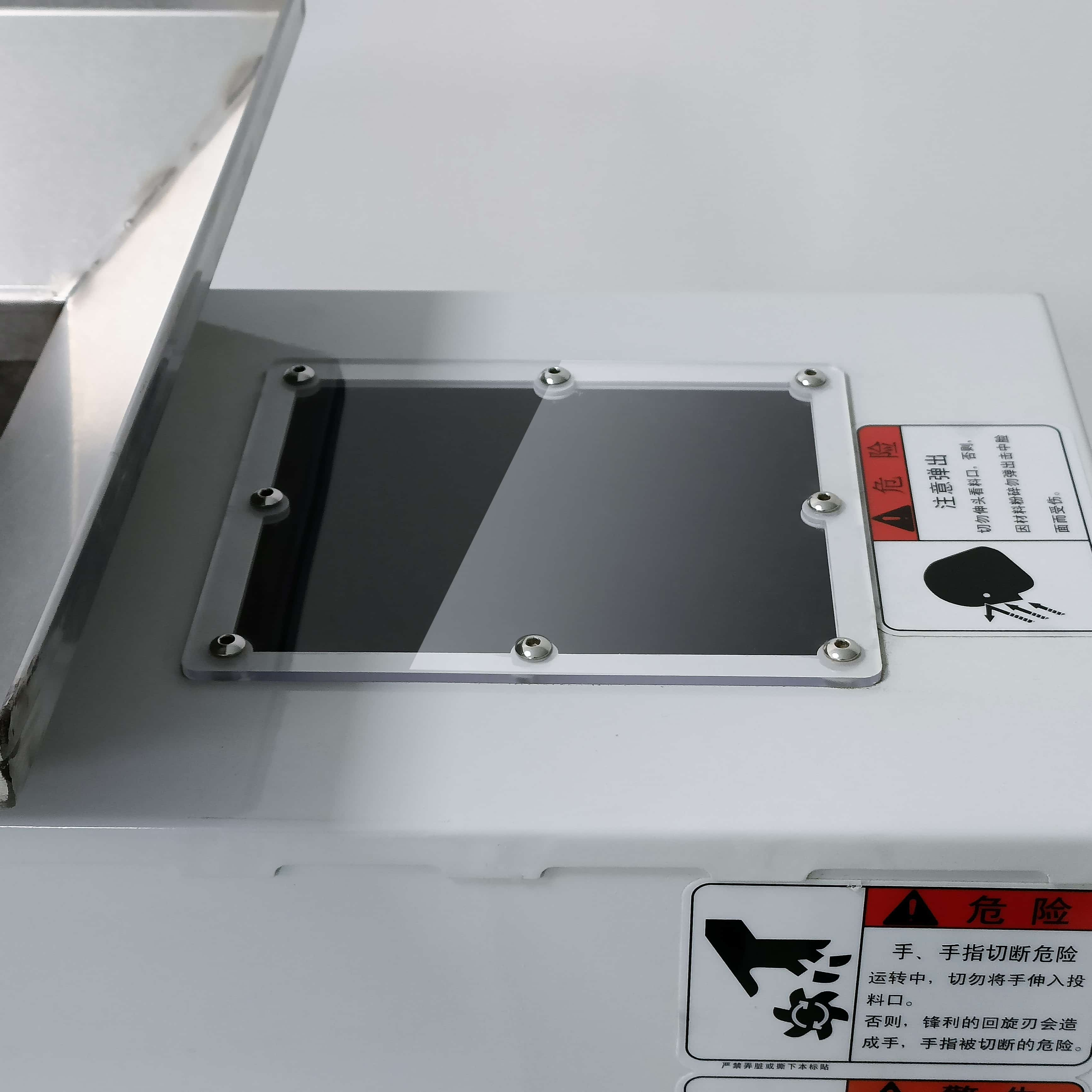

✅Visual Window for Intuitive Monitoring: The machine body is equipped with a visual window to observe the material status in the crushing chamber in real time, to facilitate the adjustment of crushing parameters at any time, avoid blockage or over-crushing, and make the operation process more intuitive and controllable.

Product Detail Display

A Variety of Combinations

See Which One is Right for You

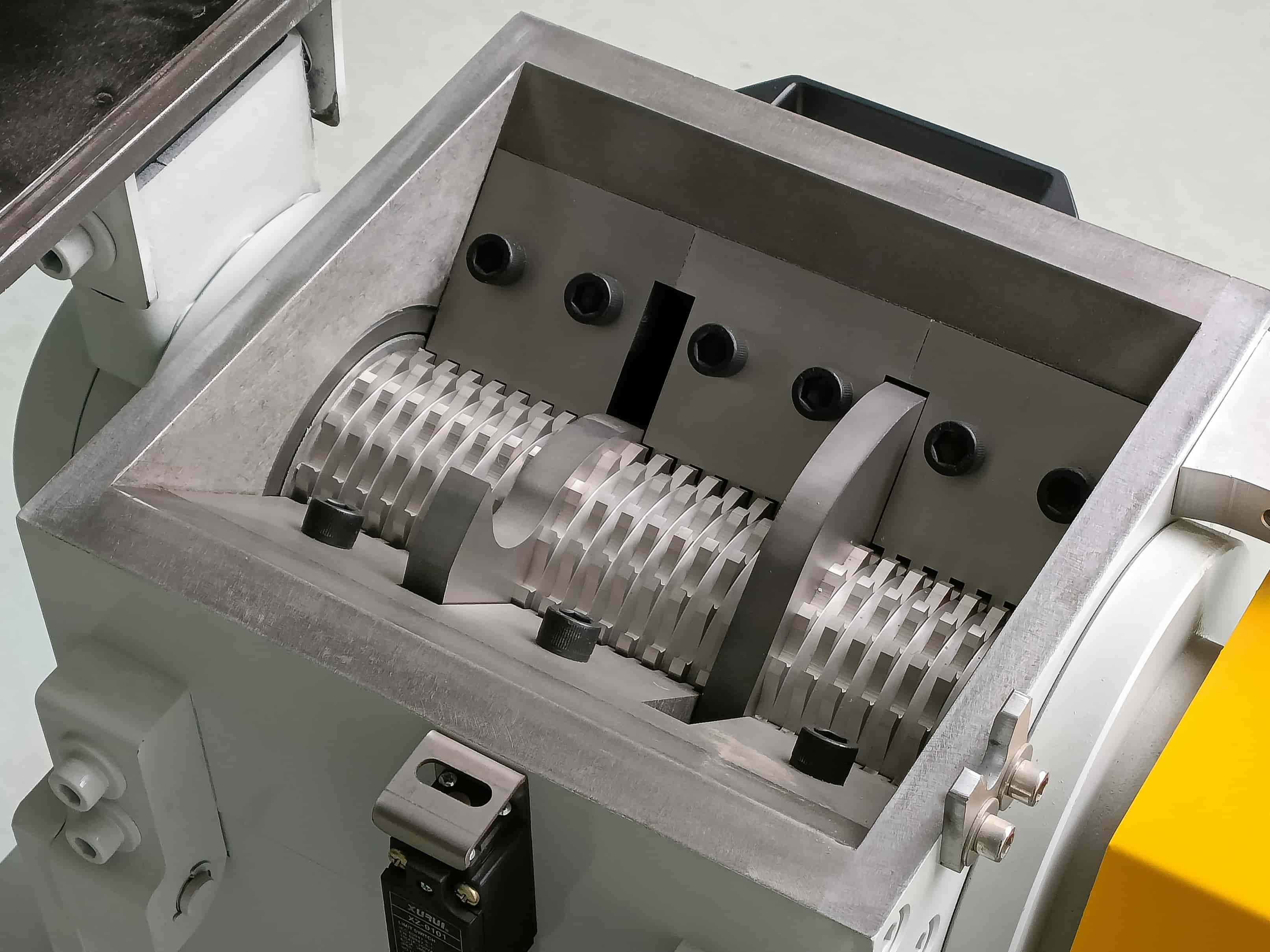

NO NEED TO SHARPEN THE KNIFE FOR TEN YEARS

HIGH TEMPERATURE QUENCHED ALLOY KNIFE

Using SKD-11 pineapple knife, high temperature quenching,

tempering forging, hardness can reach 58- 61 HRC,

hard and wear-resistant, no need to sharpen the knife for long-term use.

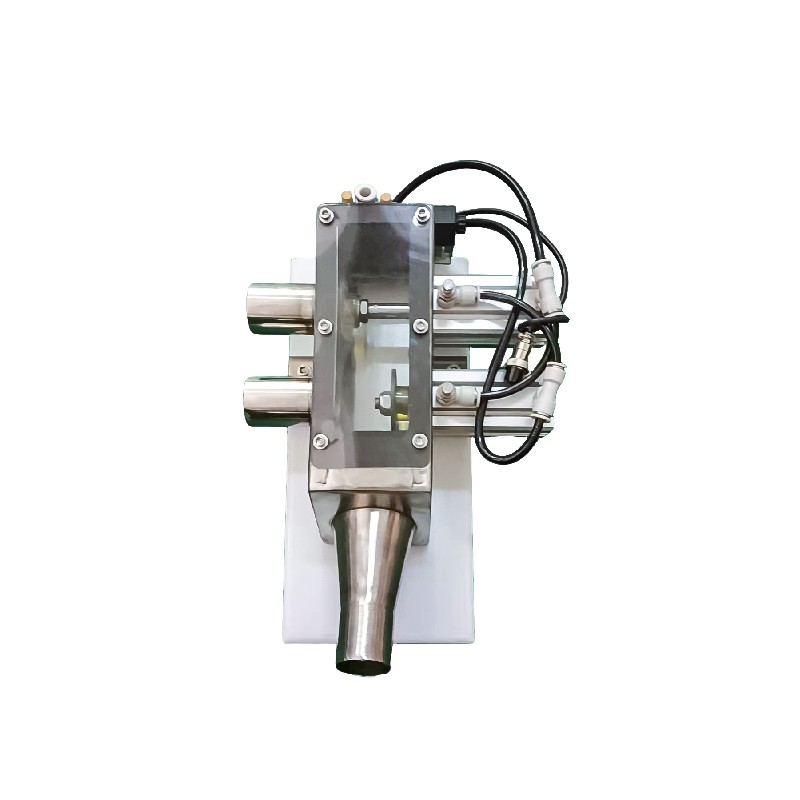

30-SECOND PARTICLE RECOVERY

NO MANUAL WORK REQUIRED

High-pressure blower, 30-second quick recovery.

No manual pouring or adding of materials required.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported