Featuring a high-performance hot air diffuser for uniform drying temperature, stainless steel contamination-free construction, and dust-resistant bent hot air pipes to prevent combustion, this plastic dryer ensures efficient drying, easy material changeover, and safe operation with precise temperature control.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

In plastic drying processes, uneven temperature, dust accumulation, and material contamination often lead to inefficiencies and quality issues. This dryer incorporates a high-performance hot air diffuser to ensure uniform heat distribution for consistent drying, significantly improving efficiency. The innovative bent hot air pipe design channels dust away from heating elements, reducing combustion risks caused by debris buildup. Constructed with stainless steel for all internal components, it eliminates material contamination—ideal for sensitive applications like medical plastics and food packaging. The detachable hopper design enables quick and easy material changes, while the precision temperature control system and thermal protection device ensure safe, reliable operation for continuous production needs.

Product Parameters

| Model | Electric Heating (kW) |

Fan (W) |

Power Supply (V) |

Capacity (kg) |

Base Installation Dimensions Length*Width*Feeding Hole (cm) |

Packaging Dimensions Length*Width*Height (cm) |

Net Weight (kg) |

| 12 | 1.8 | 75 | 220V Single-Phase Electricity |

12 | 11*11*Φ4.5 | 69*43*70 | 21 |

| 25 | 3.5 | 135 | 25 | 15*16*Φ6 | 76*46*83 | 34 | |

| 50 | 4.5 | 155 | 380V Three-Phase Electricity |

50 | 16*16*Φ7 | 85*49*93 | 38 |

| 75 | 5.5 | 155 | 75 | 16*16*Φ7.5 | 90*56*102 | 46 | |

| 100 | 6.5 | 215 | 100 | 18*18*Φ8 | 102*63*108 | 59 | |

| 150 | 9 | 215 | 150 | 18*18*Φ8 | 107*75*129 | 85 | |

| 200 | 12 | 320 | 200 | 20*20*Φ11 | 120*88*136 | 114 | |

| 300 | 15 | 320 | 300 | 23*23*Φ11.5 | 129*94*157 | 140 | |

| 400 | 18 | 340 | 400 | 28*28*Φ12 | 150*114*200 | 170 | |

| 600 | 20 | 1100 | 600 | 28*28*Φ13.5 | 158*116*240 | 280 | |

| 800 | 30 | 2200 | 800 | 35*35*Φ13.5 | 183*128*248 | 460 | |

| 1000 | 40 | 2200 | 1000 | 50*50*Φ13.5 | 202*142*248 | 680 |

Key Features

✅ Uniform Hot Air Diffusion Technology: High-performance hot air diffusion device ensures uniform plastic drying temperature, avoiding local overheating that affects raw material quality.

✅ Curved Hot Air Pipe Design: The unique curved structure guides dust away from the electric heating pipe, effectively preventing the risk of combustion caused by dust accumulation.

✅ All Stainless Steel Internal Structure: The barrel and internal parts are made of stainless steel to prevent raw materials from contacting metal, from being contaminated at the source.

✅Quick-Release Barrel Separation: The barrel and hopper can be separated quickly, and the material cleaning and replacement can be completed within 10 minutes, greatly shortening the downtime.

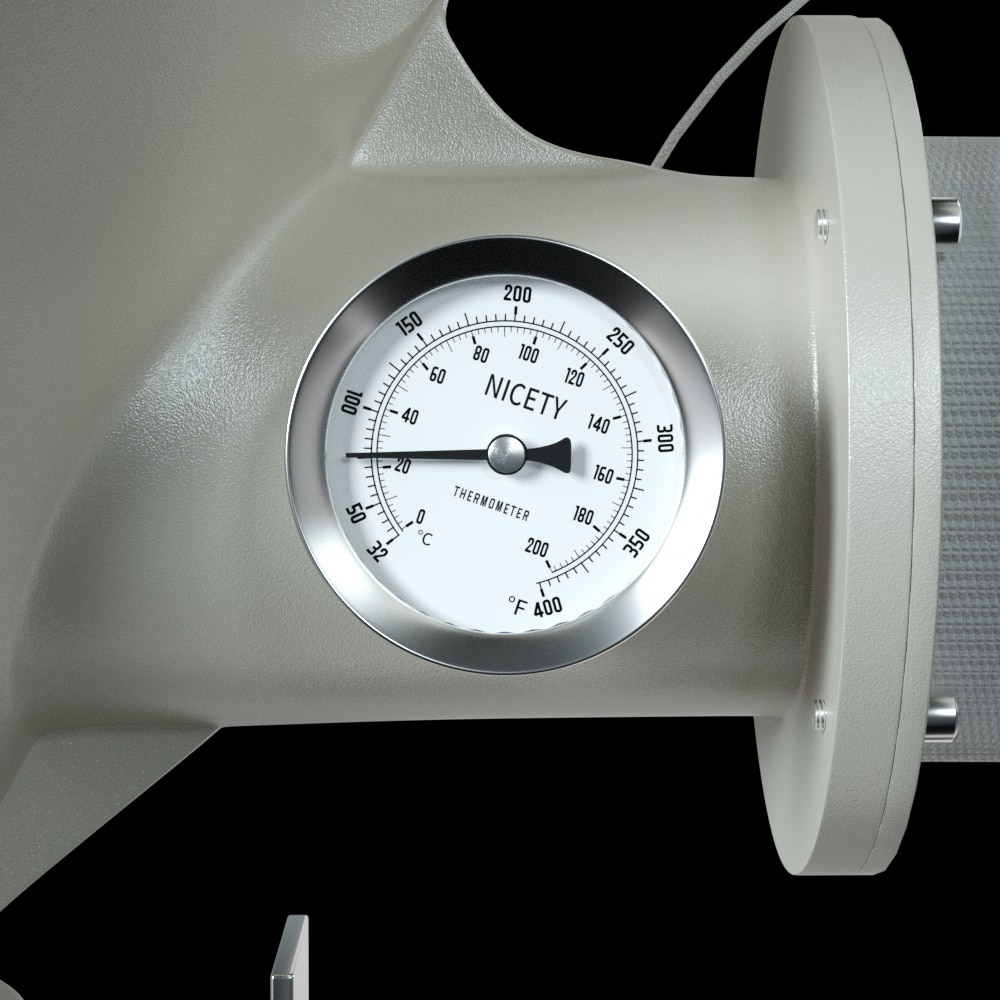

✅Precise Proportional Temperature Control: The proportional deviation indicates that the thermostat calibrates the temperature in real time to ensure the drying process is stable and controllable.

✅Double Overheat Protection: The temperature protector is combined with the heat-insulating fan to prevent the electric heating pipe from burning dry due to fan failure and extend the machine's life.

✅Dust Explosion-Proof Design: The curved pipe structure is combined with the sealing design to reduce dust retention in the heating area and improve production safety.

✅Food-Grade Cleanliness Standard: The stainless steel material complies with food contact safety standards and is suitable for drying sensitive materials such as medical consumables and food packaging.

✅Efficient and Energy-Saving Operation: The uniform hot air distribution reduces ineffective heat loss, and the energy consumption is lower than that of traditional dryers at the same production capacity.

Product Detail Display

A MACHINE TO SAVE YOUR MIND

Intelligent digital temperature controller,

automatic constant temperature with ultra-high temperature alarm function.

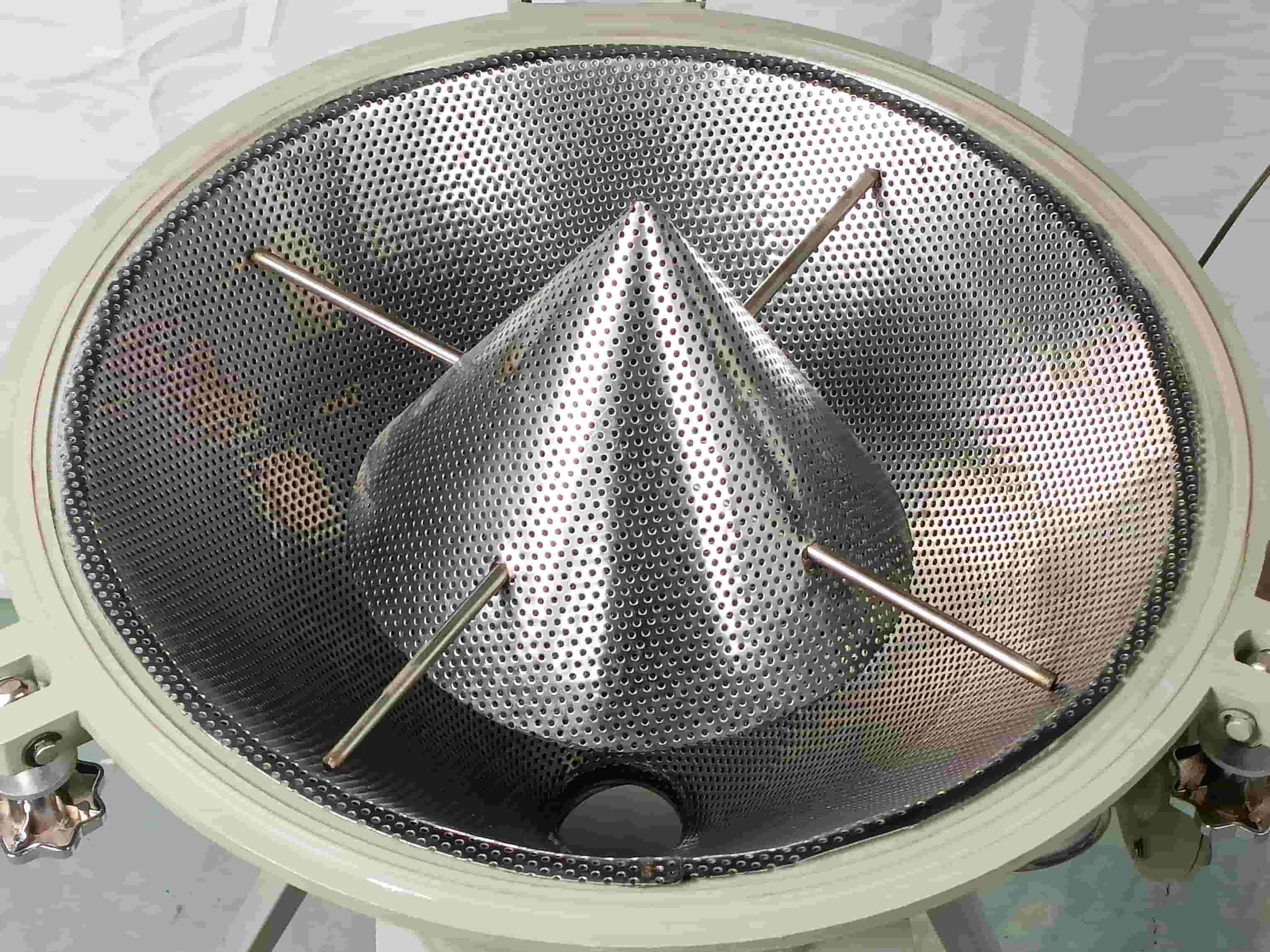

STAINLESS STEEL SCREEN DRYING EVENLY

Stainless steel screen parts,

so that the hot air evenly blows on the raw material.

FAQ

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported