Intelligent Water/Oil Dual Temperature Mold Temperature Machine with Quick Media Switching

Integrating heating-cooling, power transmission, and liquid level control systems, this dual-temperature machine uses water (maximum 120℃) and oil (maximum 180℃) for precise mold temperature control: a pump circulates heat transfer media through mold channels, temperature sensors feed real-time data to the PID controller, which automatically activates heaters or coolers to maintain ±1℃ accuracy—ideal for stable, high-quality plastic molding.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

The PQ-water/oil dual temperature mold temperature controller integrates three major systems: heating and cooling, power transmission, and liquid level control. The water (maximum 120°C) and oil (maximum 180°C) dual medium mold temperature controller circulates the heat transfer medium through the pump body. The temperature sensor feeds back data to the PID controller in real time. Automatically start and stop the heating/cooling device. Achieve ±1°C precise temperature control, providing stable temperature control guarantee for precision injection molding, rubber molding, and other processes.

Product Parameters

| Model |

DT- 6kw-W |

DT- 9kw-W |

DT- 12kw-W |

DT- 6kw-O |

DT- 9kw-O |

DT- 12kw-O |

| Heat Transfer Medium | Water | Thermal Oil | ||||

| Maximum Temperature | 120℃ | 180℃ | ||||

| Heating Power (kW) | 6×2 | 9×2 | 12×2 | 6×2 | 9×2 | 12×2 |

| Pump Power (kW) | 0.37×2 | 0.37×2 | 0.75×2 | 0.37×2 | 0.37×2 | 0.75×2 |

| Maximum Pump Flow (L/min) |

42L×2/min | 42L×2/min | 56L×2/min | 42L×2/min | 42L×2/min | 56L×2/min |

| Pump Head (M) | 28 | 28 | 38 | 28 | 28 | 38 |

| Mold Inlet and Outlet Diameter |

3/8"× 8pc s |

3/8"× 16pc s |

3/8"× 16pc s |

3/8"× 8pc s |

3/8"× 16pc s |

3/8"× 16pc s |

| Dimensions (H×W×D cm) | 90×40×98 | 90×40×98 | 90×40×98 | 90×40×98 | 90×40×98 | 90×40×98 |

Key Features

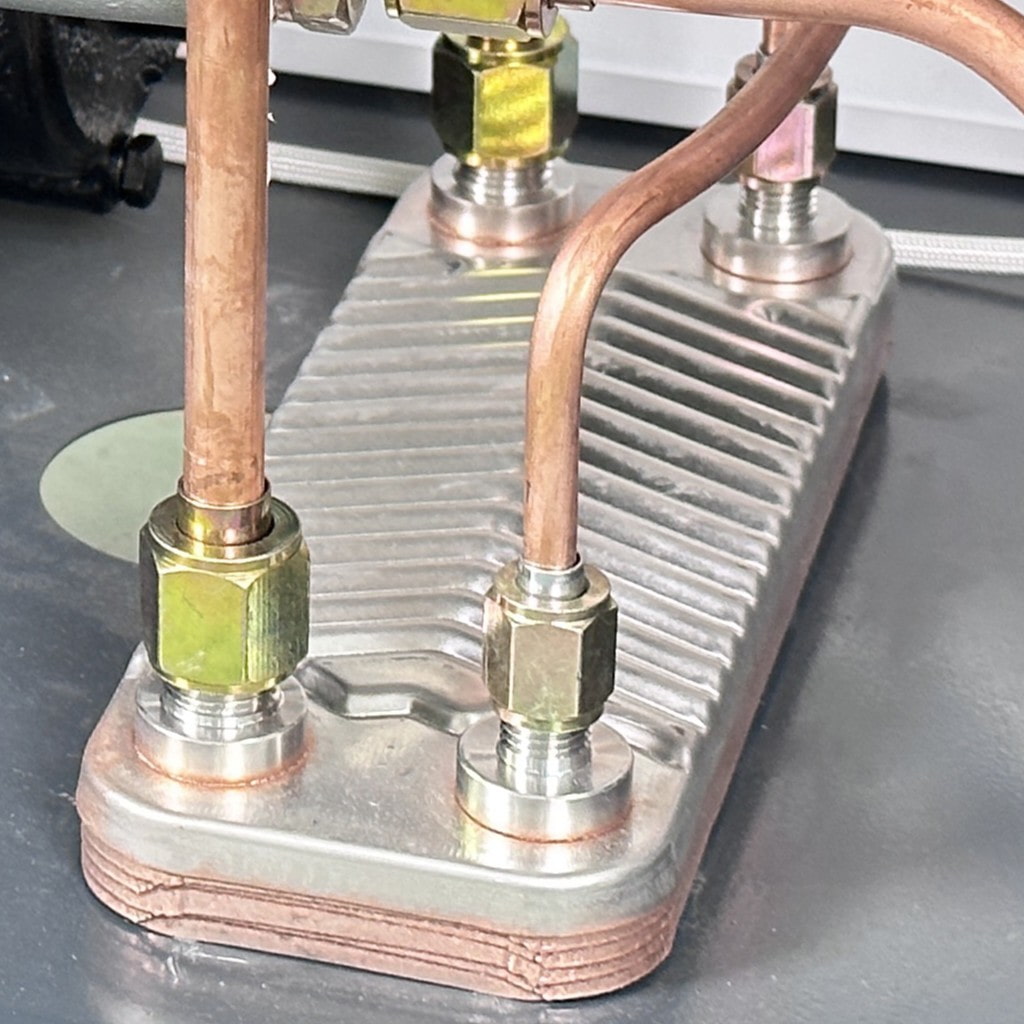

✅ Stainless Steel Plate Heat Exchanger: The plate structure is made of stainless steel, with high indirect cooling efficiency, quick response to mold temperature changes, effective temperature balance, and reduced damage to the mold caused by thermal stress.

✅ Brand High-Temperature Resistant Pump: Equipped with a low-noise pump that is resistant to high pressure and high temperature, it has stable and reliable operation and long service life, ensuring stable medium circulation in 24-hour continuous production.

✅ Stainless Steel Heating Tube: Built-in 304 stainless steel heating tube, excellent thermal conductivity and corrosion resistance, adapting to the high temperature heating requirements of various media, and is not easy to scale after long-term use.

✅All-Copper High Temperature Resistant Interface: The inlet and outlet adopt pure copper joints, with strong high temperature resistance, and different power models are configured with the number of interfaces (two in and two out / four in and four out), supporting multi-mold connection, and convenient and efficient mold change operation.

✅High-Precision Solenoid Valve: Select solenoid valves with high control accuracy and low failure rate, which can sensitively adjust the cooling system according to temperature changes, improving production reliability.

✅Dual-Medium Anti-Corrosion Design: From heat exchangers, heating pipes to pipeline interfaces, the entire link is made of stainless steel and pure copper, which has strong corrosion resistance and is suitable for long-term use of aqueous media containing release agents or high-temperature heat transfer oil.

✅Multi-Scenario Adaptation: Provide different power models to adapt to temperature control requirements, support various molding processes such as injection molding and extrusion, and have a wide range of application scenarios.

Product Detail Display

THE INTERNAL STRUCTURE OF THE PRODUCT

The internal structure diagram of the product helps to

have a more comprehensive understanding of the machine.

PURE COPPER CORE HIGH-FLOW WATER PUMP

It adopts high temperature, high pressure resistance, and low noise pumping.

Stable operation and long service life.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported