Designed for easy operation, the automatic suction machine is equipped with a stainless steel material door, motor protection device and standard cloth filter. It has an integrated low-material alarm function and is easy to maintain. It is suitable for direct installation at the inlet of the molding machine.

ItemNO:

850GOrder(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

In plastic production, manual feeding can easily lead to dust pollution, uneven feeding, and safety hazards, while the 850G auto loader effectively solves these problems. The equipment is equipped with an intelligent vacuum pump and an adjustable suction system to automatically transport granular raw materials from the storage barrel to the processing equipment, and the sealed dust removal and filtration system prevents external dust from entering the hopper. The quick-release barrel design supports seamless switching of multiple materials such as PA, PET, PC, etc. in a short time, which is especially suitable for multi-variety production lines. The built-in overload protection device detects blockage or motor failure in real time, automatically shuts down to avoid damage, and ensures the safety of operators. The ultimate realization: a reliable, efficient, and dust-free feeding solution that integrates seamlessly with existing production lines.

Product Parameters

| Model | 850G |

| Motor Type | Induction Type |

| Motor Specification | 1.5kW3Ø |

| Voltage | 380V |

| Fan-Out Capability (kg/h) | 450 |

| Feed Delivery Pipe | 38MM |

| Storage Bucket Capacity (L) | 7.5 |

| Storage Bucket Size (cm) | 40×30×50 |

| Body Weight (kg) | 58 |

| Storage Vat (kg) | 6 |

| Body Size (cm) | 44×37×70 |

Key Features

✅ Stainless Steel Material Door Is Corrosion-Resistant: The material door is made of stainless steel, which is dust-resistant and moisture-resistant, adapts to the complex environment of the injection molding workshop, and extends the service life of the equipment.

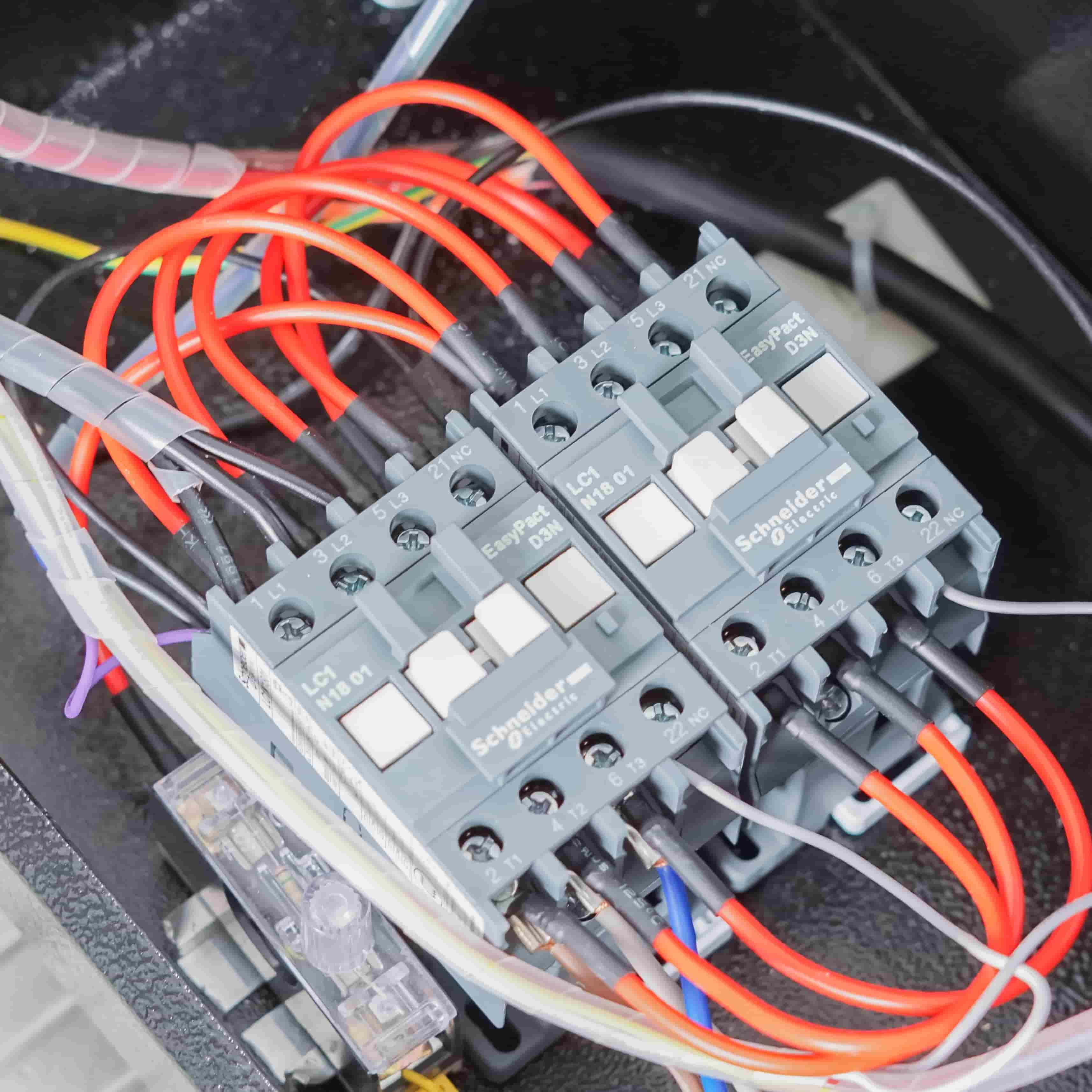

✅ Motor Overload Protection: The built-in motor protection device monitors the load status in real time, automatically shuts down when overloaded, and effectively avoids the risk of motor burning.

✅ Real-Time Reminder Of Material Shortage Alarm: Audible alarm alerts operators immediately when materials run low, preventing production line interruptions.

✅Quick-Release Barrel Separation: The barrel and hopper can be separated quickly, and the material cleaning and replacement can be completed within 10 minutes, greatly shortening the downtime.

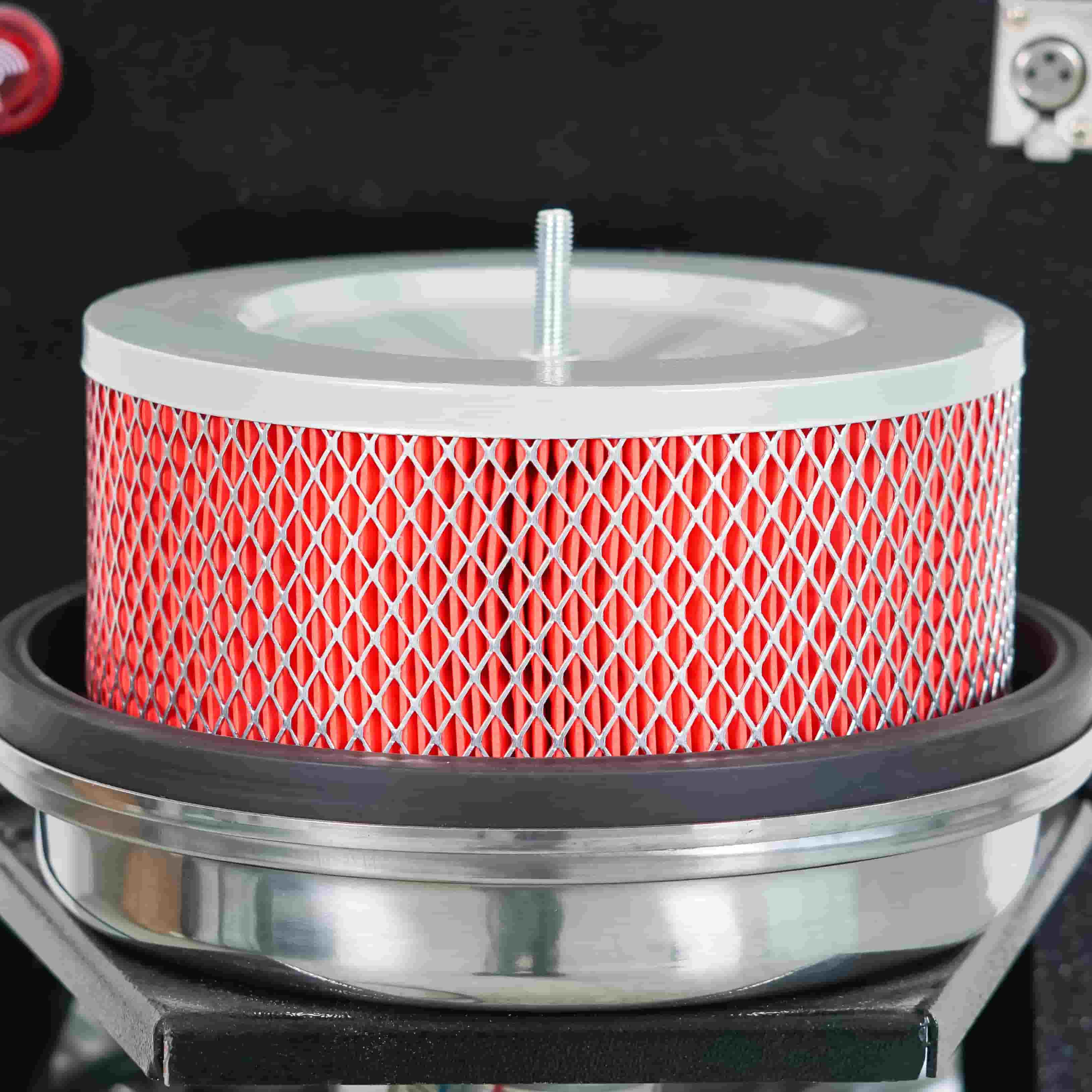

✅Standard Configuration Of Cloth Filter: Standard high-precision cloth filter to filter dust impurities, ensure the cleanness of the conveyed raw materials, avoid mold blockage, and product defects.

✅Direct Connection Design Of Molding Machine: The ZAL-300E model is equipped with a beam photoelectric switch, which can be directly installed at the inlet of the molding machine, eliminating complex pipeline connections and improving feeding efficiency.

✅Dust Explosion-Proof Design: The curved pipe structure is combined with the sealing design to reduce dust retention in the heating area and improve production safety.

✅Simple Operation Interface: There is no complex button design, and it runs automatically after power-on. Novices can also get started quickly, reducing training costs.

✅Multi-Scenario Adaptation: Compatible with various plastic particles such as PA, PET, PC, etc., suitable for various molding processes such as injection molding and extrusion to meet diverse production needs.

Product Detail Display

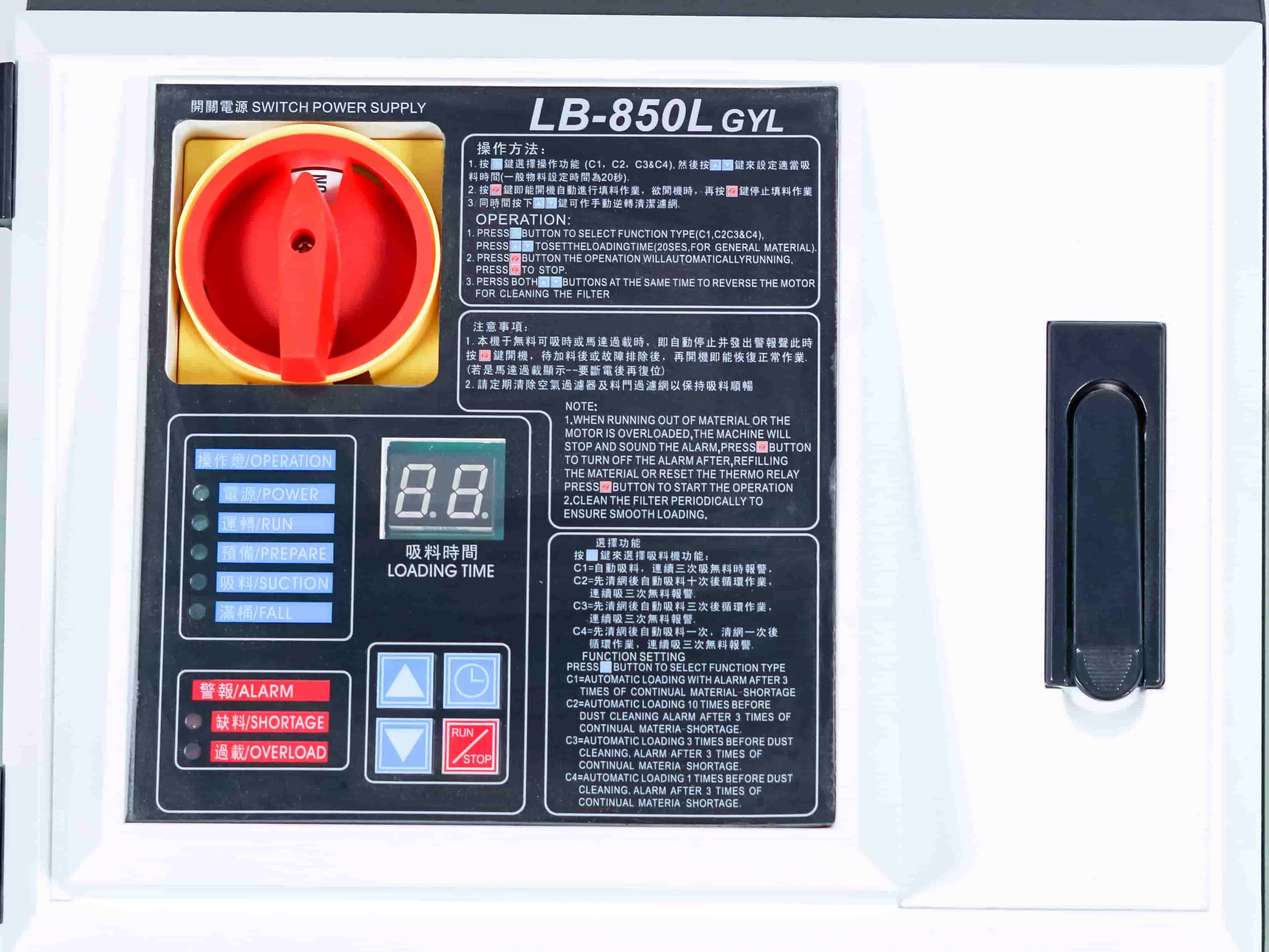

MICROCOMPUTER CONTROL PANEL

SIMPLE OPERATION

Automatic feeding, time adjustable,

lack of material or motor overload stop, and alarm.

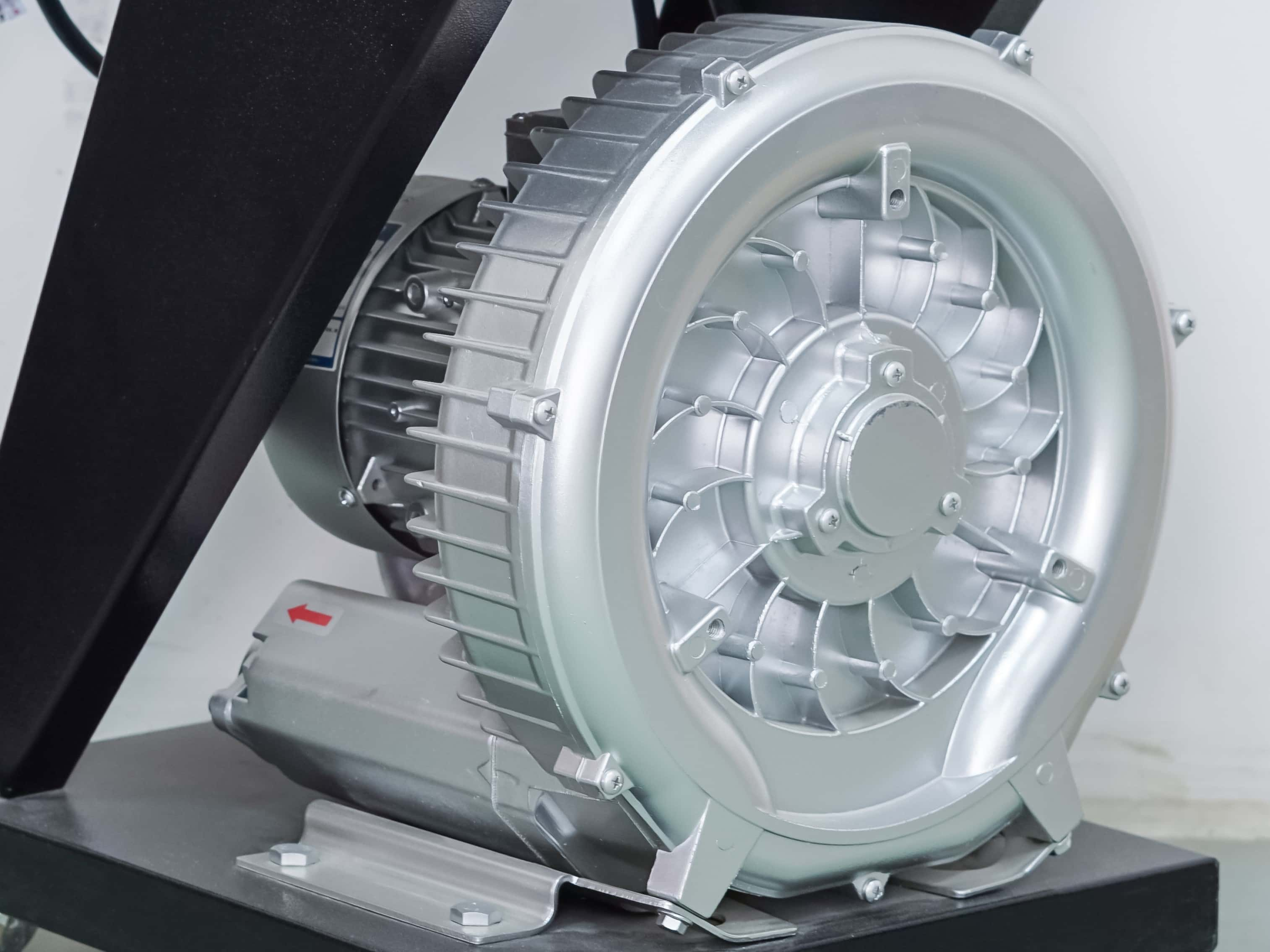

A HIGH-PRESSURE FEEDING FAN

CAN RUN FOR A LONG TIME

Induction-type high-power fan, large suction, faster loading.

Long service life, can be a long time of uninterrupted work.

PURE COPPER CORE MOTOR

Copper core carbon brush motors

small size, high efficiency, stable operation.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported