Water/Oil Type Mold Temperature Machine with Efficient Heat Transfer

PQ water/oil type mold temperature machine provides two customized models: water type (maximum 180℃) and oil type (maximum 300℃). It is equipped with a microcomputer intelligent control to achieve ±1℃ precise temperature control. The stainless steel heating barrel has passed high-pressure explosion-proof certification, providing a stable and reliable mold temperature control solution for plastic molding.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQ

Product Description

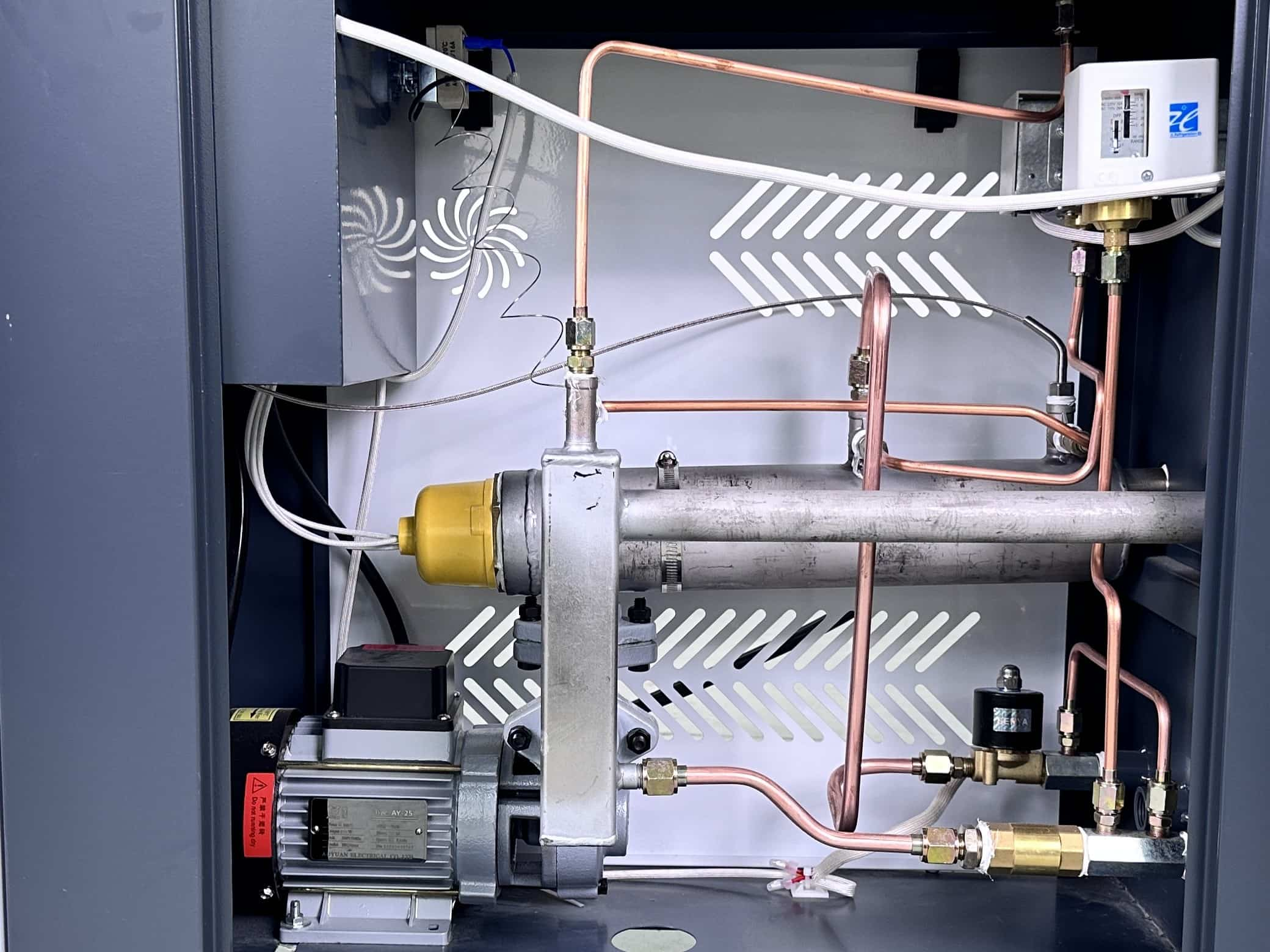

In plastic production, accurate mold temperature control is the key to ensuring product quality and production efficiency. This machine uses water (for medium temperature scenarios) or oil (for high temperature scenarios) as the heat transfer medium to ensure that the mold surface is evenly heated. The durable pump body drives the medium to circulate stably, and the stainless steel heat exchanger and high-quality heating elements are corrosion-resistant and anti-scaling, and can maintain performance even after long-term use of water-based release agents or thermal oils. The user-friendly control panel makes it easy to set the target temperature, and safety features such as anti-dry burn protection and overheating alarm prevent equipment damage. Whether using water to cool PVC soft products or using oil to heat engineering plastics such as PA/PC, it can provide stable and reliable temperature control solutions to reduce defects and improve yield rates.

Product Parameters

| Model | 6KW-W | 9KW-W | 12KW-W | 6KW-O | 9KW-O | 12KW-O |

| Heat Transfer Medium | Water | Thermal Oil | ||||

| Maximum Temperature | 120℃ | 180℃ | ||||

| Heating Power (kW) | 6 | 9 | 12 | 6 | 9 | 12 |

| Pump Power (kW) | 0.37 | 0.37 | 0.75 | 0.37 | 0.37 | 0.75 |

| Maximum Pump Flow (L/min) | 42L/min | 42L/min | 56L/min | 42L/min | 42L/min | 56L/min |

| Pump Head (M) | 28 | 28 | 38 | 28 | 28 | 38 |

| Number of Interfaces | Two in, two out |

Four in, four out |

Four in, four out |

Two in, two out |

Four in, four out |

Four in, four out |

| Mold Inlet and Outlet Diameter | 3/8"×4pc s | 3/8"×8pc s | 3/8"×8pc s | 3/8"×4pc s | 3/8"×8pc s | 3/8"×8pc s |

| Dimensions (H×W×D cm) | 67×30×66 | 67×30×66 | 67×30×66 | 67×30×66 | 67×30×66 | 67×30×66 |

| Net Weight (kg) | 50 | 54 | 58 | 48 | 50 | 60 |

Key Features

✅ Flexible Adaptation of Dual Styles: Two customized models, water type and oil type, are provided to meet the needs of medium and low temperature cooling and high temperature heating, respectively, easily cope with the molding temperature control of different materials, and adapt to various processes such as injection molding and extrusion.

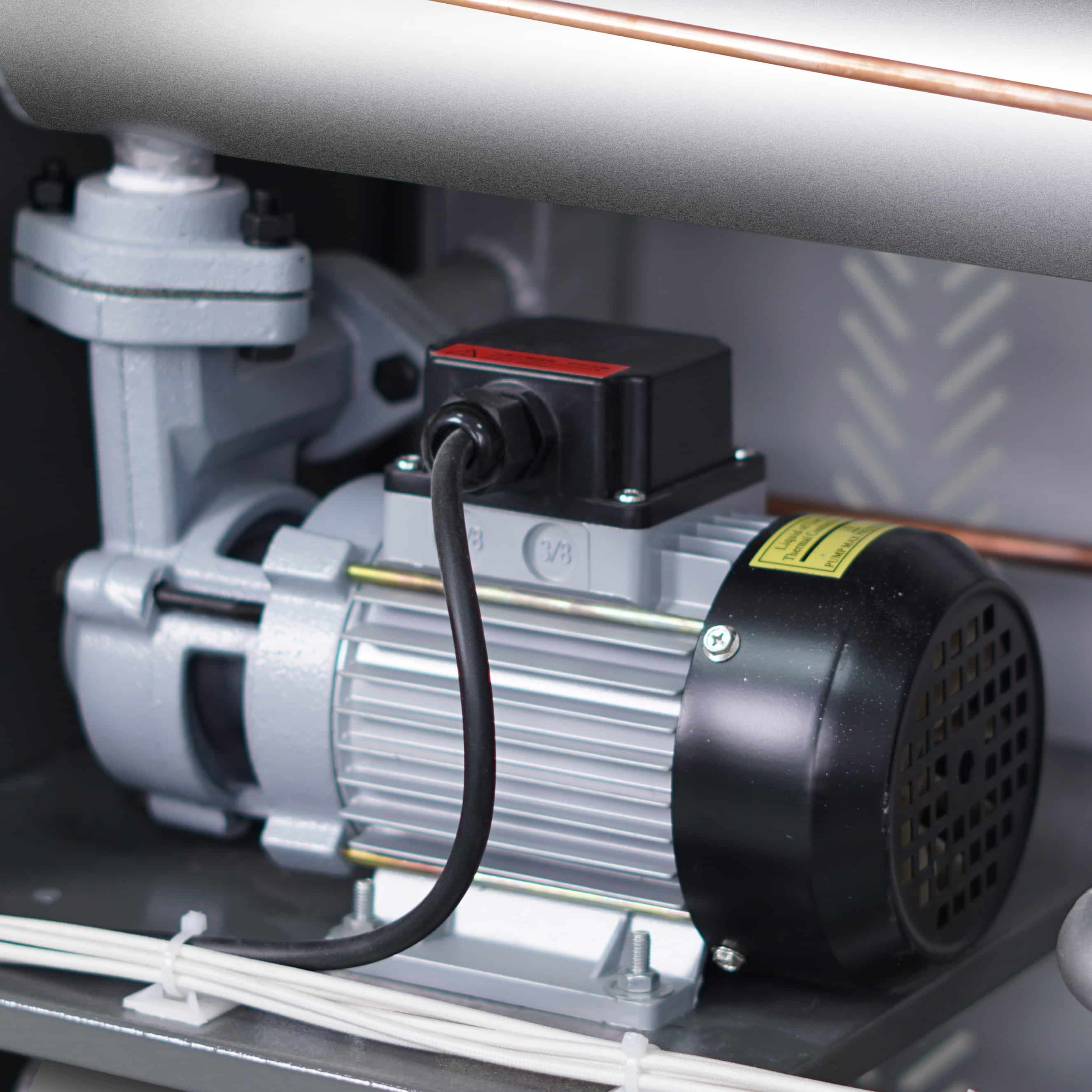

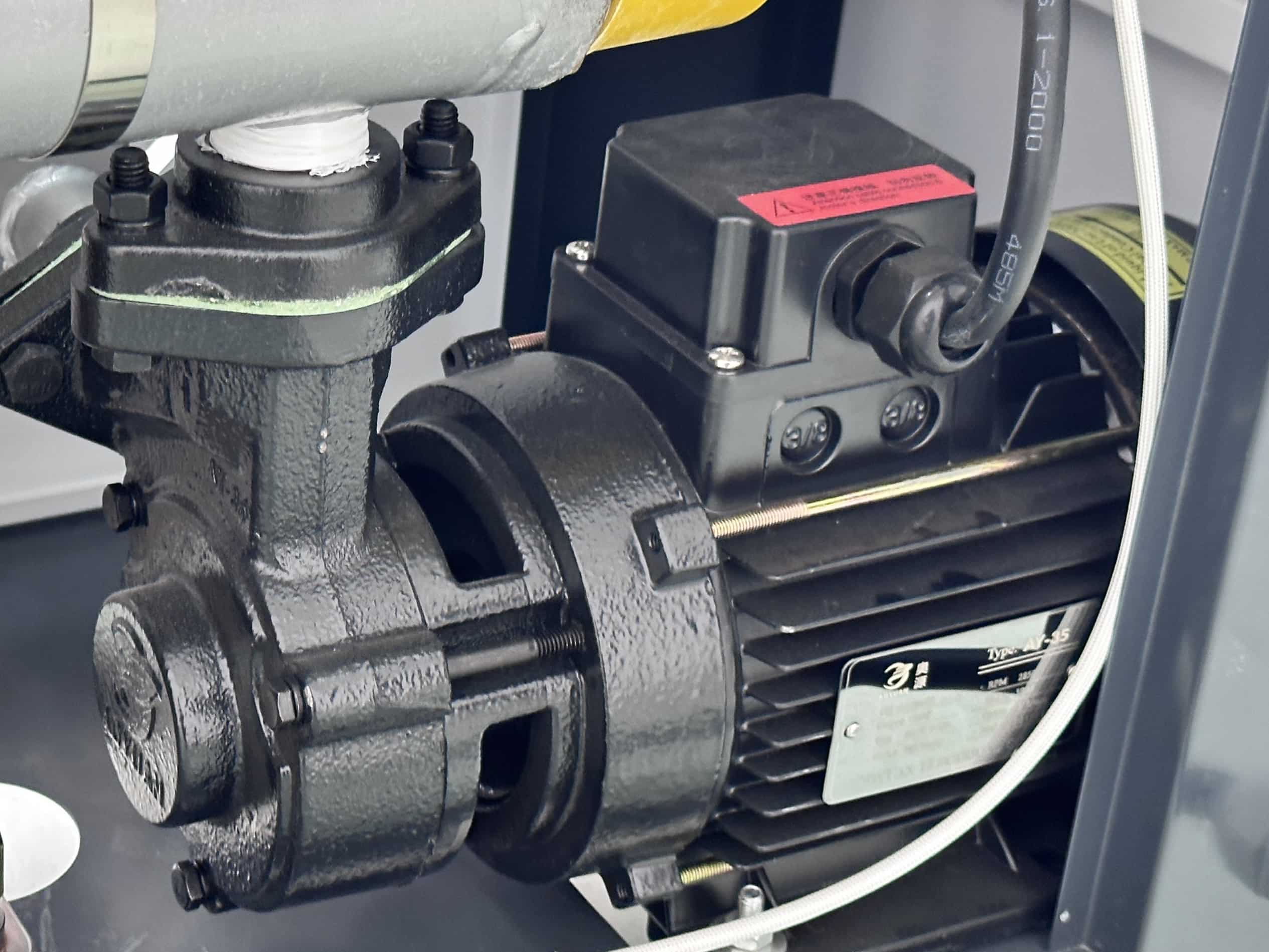

✅ Brand High-Temperature Resistant Pump: Equipped with a low-noise pump that is resistant to high pressure and high temperature, it has stable and reliable operation and long service life, ensuring stable medium circulation in 24-hour continuous production.

✅ Stainless Steel Heating Tube: Built-in 304 stainless steel heating tube, excellent thermal conductivity and corrosion resistance, adapting to the high temperature heating requirements of various media, and is not easy to scale after long-term use.

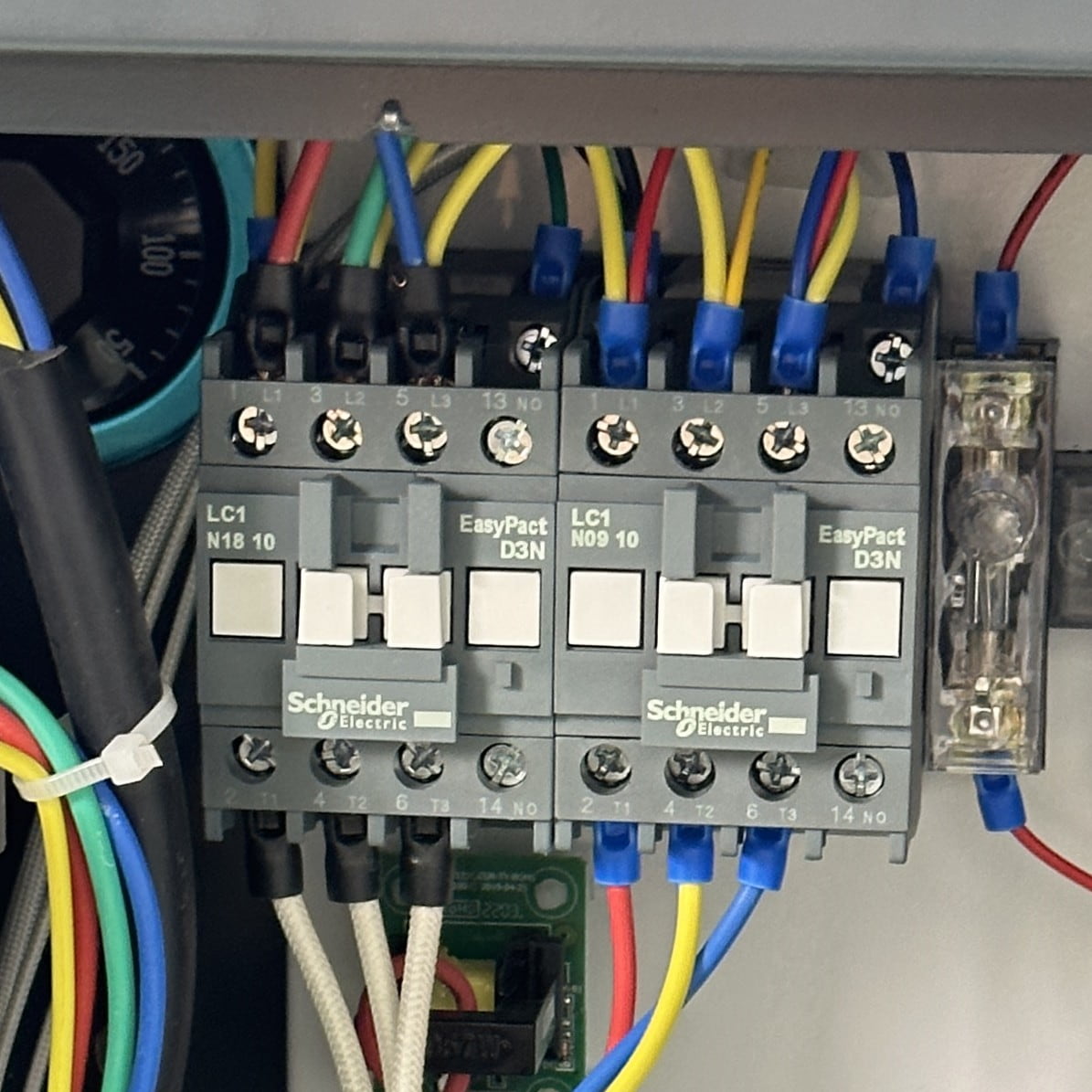

✅Intelligent and Precise Temperature Control: Equipped with a microcomputer controller, it automatically adjusts heating and cooling in real time, effectively controls mold temperature fluctuations, reduces product defects caused by uneven temperature, and provides a stable temperature environment for high-quality molding.

✅Humanized Intelligent Operation: The operation interface supports the storage of multiple sets of temperature control solutions, and preset parameters can be quickly called when changing molds, simplifying manual adjustment steps.

✅Stable Thermal Fluid Circulation: Equipped with a temperature-resistant and high-pressure pump, it drives the thermal fluid to circulate evenly to various areas of the mold, reduces local temperature differences, improves the consistency of mold surface temperature, and provides a stable heat conduction guarantee for precision molding.

✅Multi-Scenario Adaptation: Provide different power models to adapt to temperature control requirements, support various molding processes such as injection molding and extrusion, and have a wide range of application scenarios.

Product Detail Display

HEATS UP QUICKLY IN ONE MINUTE

Bangpu microcomputer control panel

Stable and constant temperature ±1°C

THE INTERNAL STRUCTURE OF THE PRODUCT

The internal structure diagram of the product helps to

have a more comprehensive understanding of the machine.

PURE COPPER CORE HIGH-FLOW WATER PUMP

It adopts high temperature, high pressure resistance, and low noise pumping.

Stable operation and long service life.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported